1. One-Stop Service

2. Modular Flexible Design

3. Selectable Automation Levels

4. Intelligent Manufacturing Support

5. Quality Monitoring Assurance

6. High Efficiency and High Productivity

7. Human-Centric Engineering Optimization

8. Safe and Environmentally Friendly Design

9. Technical Training and Maintenance

10. Customized Development

Product Description

1. Keywords:

Battery module assembly equipment, lithium-ion battery module assembly platform, automated module assembly line, cell assembly equipment, busbar assembly machine, module assembly production line,Automated Battery Module Assembly Line,Cell Module Assembly System

2. Introduction:

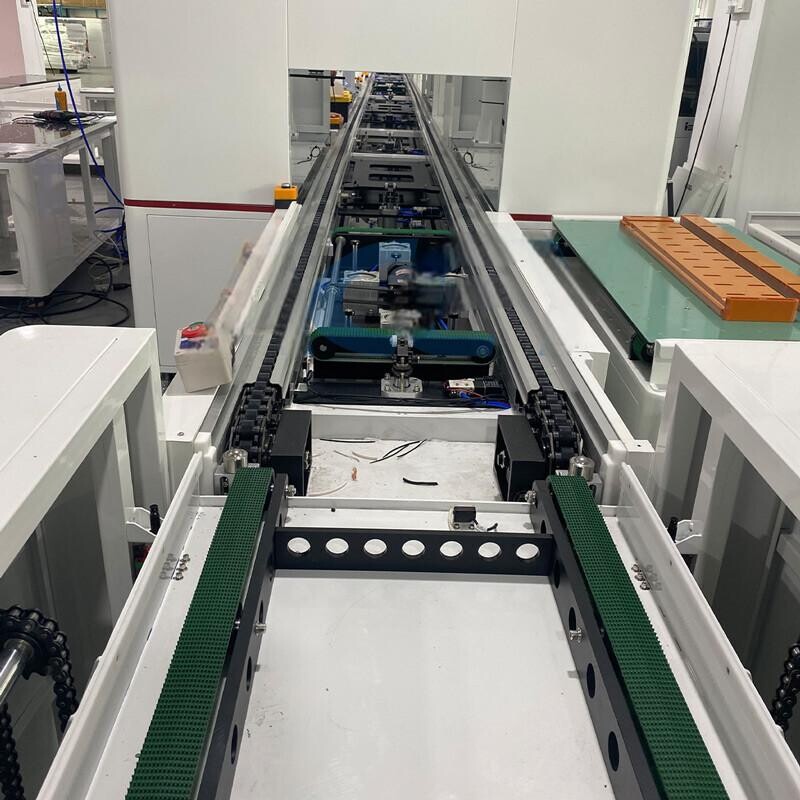

The assembly platform is the core equipment for assembling cells, busbars, structural components, and other parts to form complete battery modules. It can be a manual assembly line, semi-automated assembly line, or fully automated assembly line, depending on the production scale and automation requirements. The automated assembly platform achieves an efficient and precise assembly process through robotic arms, conveyors, positioning devices, and more, ensuring product quality and consistency. It plays a crucial role in the production of lithium-ion battery modules and packs.

3. Working Process:

Material preparation: Feeding of cells, busbars, structural components, etc.

Cell arraying and alignment.

Busbar installation and welding.

Structural component assembly: Brackets, housings, screw fastening.

BMS and wiring harness installation.

Potting and sealing.

Quality inspection: Vision inspection, electrical performance testing.

Module unloading and output.

4. Technical Specifications:

Applicable Products: Power battery modules, energy storage battery modules, consumer electronics battery modules.

Cell Specifications: Cylindrical, prismatic, pouch cells, customizable dimensions.

Production Rate: Manual 20-40 modules/shift, Automated 20-60 modules/hour.

Automation Level: Manual, semi-automated, or fully automated options.

Equipment Size: Customized for manual lines, automated lines approx. 50-200 sq.m.

Control System: PLC control, MES system integration capable.

Power Supply: AC 380V, 50Hz, approx. 20-100kW.

Air Source: 0.5-0.7MPa compressed air.

5. Technical Features:

Modular design, flexible layout, adaptable to different products and capacities.

Automated assembly, improved efficiency, enabling unmanned or minimally manned operation.

High-precision positioning, quality control, ensuring assembly accuracy and quality.

Intelligent control system, supporting multi-process programming and data management.

Human-centric design, convenient operation, safety protection measures.

High compatibility, suitable for various cells and modules, easy to upgrade and expand.

6. Application:

New energy vehicle power battery module production.

Energy storage system battery module production.

Power tool and light electric vehicle battery module production.

Consumer electronics battery module production.

Other specialty equipment and backup power system battery module production.

Lithium Battery Intelligent Production Line Solution

Partners

Certificates

Send me a free quote

Related Products

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support