1. One-Stop Service

2. Modular Flexible Design

3. Selectable Automation Levels

4. Intelligent Manufacturing Support

5. Quality Monitoring Assurance

6. High Efficiency and High Productivity

7. Human-Centric Engineering Optimization

8. Safe and Environmentally Friendly Design

9. Technical Training and Maintenance

10. Customized Development

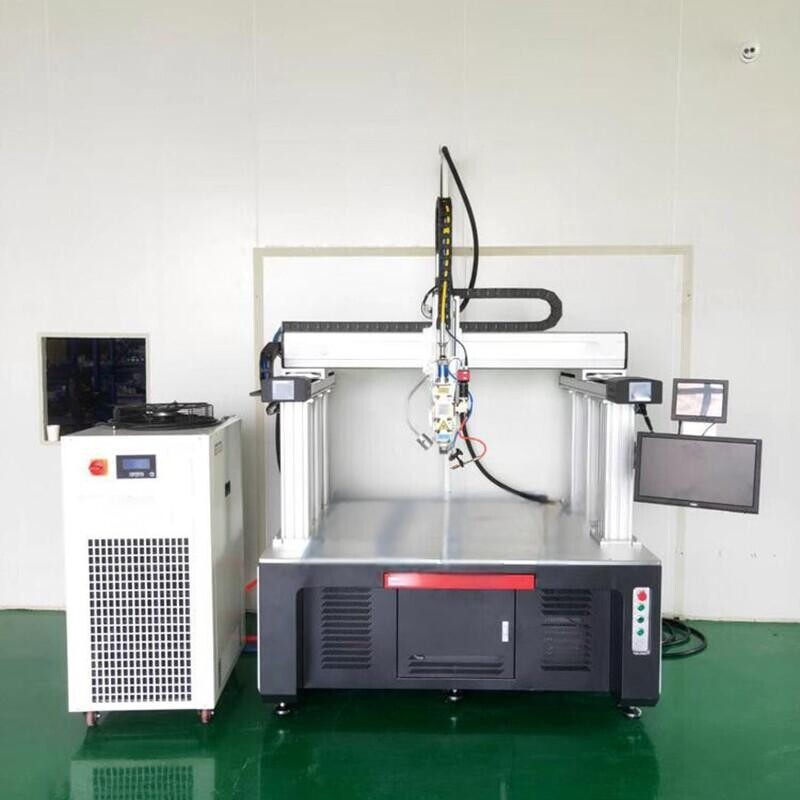

Product Description

1. Keywords:

Laser welding equipment, lithium battery laser welding machine, high precision metal welding machine, busbar laser welding, battery terminal welding machine, precision laser welding

2. Introduction:

The high precision laser welding machine is a device that uses a high-energy density laser beam to precisely weld metal components. It achieves high-strength, low-deformation welding with advantages such as high welding accuracy, fast speed, and small heat-affected zones. It is particularly suitable for welding critical areas like busbars, terminals, and cell tabs in lithium battery module and pack production. Adopting advanced control systems and optical components, it meets high-standard, high-quality production requirements.

3. Working Process:

Workpieces are placed on dedicated welding fixtures for precise positioning and fixation.

Laser parameters such as power, frequency, and welding speed are set according to the material.

The laser beam is delivered and focused through a fiber optic cable, precisely irradiating the welding area.

The laser energy concentrates and melts the metal to form a weld pool, which solidifies into a weld seam upon cooling.

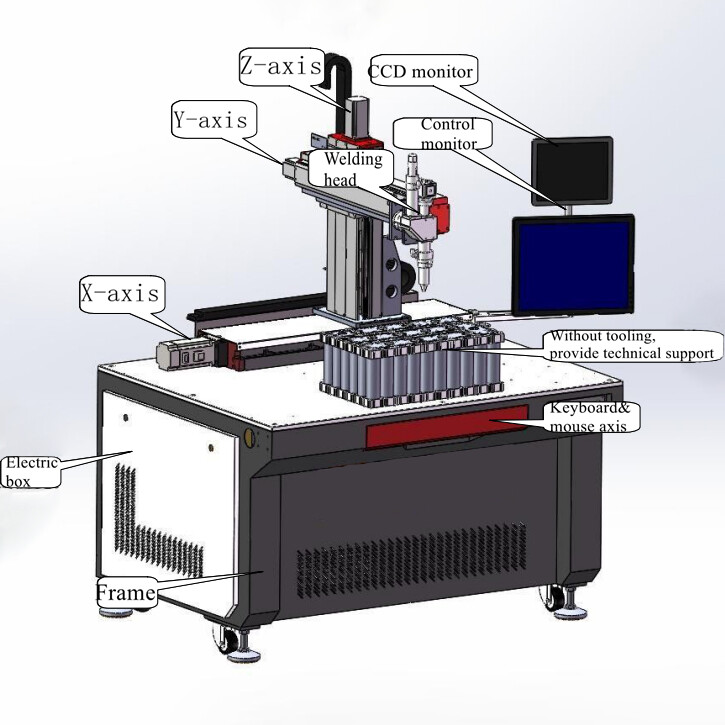

A robot or motion platform controls the movement of the laser head to complete complex welding paths.

An online monitoring system continuously monitors the welding process to ensure stable quality.

4. Technical Specifications:

Laser Type: Fiber laser, semiconductor laser, etc.

Laser Power: 500W - 6000W (selectable).

Laser Wavelength: 1064nm (near-infrared).

Pulse Frequency: 1Hz - 5000Hz (adjustable).

Welding Speed: 0.1m/min - 15m/min.

Positioning Accuracy: ±0.02mm.

Repeatability: ±0.01mm.

Motion System: 3-axis CNC workstation or robotic system.

Control System: Industrial PC or PLC control.

Power Supply: AC 380V, 50Hz.

5. Technical Features:

High welding accuracy, capable of micron-level precision welding

Excellent weld quality, deep penetration, small heat-affected zone, high strength

Wide range of applicable materials, including aluminum, copper, steel, alloys, etc.

High flexibility, capable of spot welding, seam welding, lap welding, and more

High degree of automation, can be integrated with robotic systems

Environmentally friendly and safe, non-contact and pollution-free

Real-time monitoring to ensure stable welding quality

User-friendly operation, convenient parameter setting, and program storage

6. Application:

Welding of large battery modules for electric vehicles, energy storage systems, etc.

Precision component welding for small batteries in consumer electronics.

Precision welding for electronics, medical devices, aerospace, etc.

Welding of small components in precision machinery, optoelectronics, etc.

Lithium Battery Intelligent Production Line Solution

Partners

Certificates

Send me a free quote

Related Products

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support