1. One-Stop Service

2. Modular Flexible Design

3. Selectable Automation Levels

4. Intelligent Manufacturing Support

5. Quality Monitoring Assurance

6. High Efficiency and High Productivity

7. Human-Centric Engineering Optimization

8. Safe and Environmentally Friendly Design

9. Technical Training and Maintenance

10. Customized Development

Product Description

1. Keywords:

Automatic Screw Fastening Equipment, Lithium Battery Module Screwing Machine, Screw Fastening Machine, Torque-Controlled Screwing Machine, Automatic Screw Tightening Equipment, Precision Screw Fastening System,Automatic Screwing Machine,Screw Tightening Machine

2. Introduction:

The automatic screw fastening machine is a device used for automated fastening of various screws and bolts during the battery module assembly process. Through robotic arms, automatic feeding systems, and precise torque control, it achieves automatic screw feeding, positioning, and tightening processes, ensuring secure connections of structural components. It can set torque values, fastening speeds, and sequences according to requirements, improving production efficiency and assembly quality while reducing manual operation errors. It is a key equipment in lithium-ion battery module and pack production lines.

3. Working Process:

Automatic screw feeding.

Product positioning and fixation.

Robotic arm screw picking.

Vision or mechanical positioning.

- Servo motor tightening and fastening, torque monitoring.

Fastening data recording, anomaly handling.

Repeated fastening for remaining screws.

Product transfer to the next process.

4. Technical Specifications:

- Applicable Screw Specifications: M1.0-M6.0, 4-30mm length, iron/steel/stainless steel material.

- Fastening Torque Range: 0.05-10Nm, accuracy ±0.03Nm or ±3%.

- Fastening Speed Range: 100-1000rpm adjustable.

- Production Rate: 1.5-3 seconds per screw, 1200-2400 screws/hour.

- Control System: PLC or Industrial PC, touch screen.

- Feeding Method: Air blow feeding / Robotic arm picking.

- Positioning Accuracy: Position repeatability ±0.02mm.

- Data Recording: Fastening parameters saved for each screw.

- Power Supply: AC 220V, 50Hz, 2-5kW.

- Air Source: 0.5-0.7MPa compressed air.

- Dimensions: Approx. 1200 x 1000 x 1800mm.

5. Technical Features:

- High-precision servo motor torque control with angle feedback.

- Fully automated operation, reducing manual intervention.

- Flexible adaptation to different product specifications, rapid changeover.

- Intelligent control, adjustable fastening parameters.

- Real-time monitoring, fastening data management, quality traceability.

- Fault detection, anomaly handling, ensuring fastening quality.

- User-friendly interface, easy operation, safety protection.

- Improved efficiency, reduced labor costs and rework rates.

6. Application:

- Assembly of large battery modules for electric vehicles, energy storage systems.

- Assembly of small battery modules for power tools, electric bicycles.

- Assembly of consumer electronics, home appliances, automotive electronics.

- Assembly of industrial automation equipment, security devices.

- Screw fastening in medical devices, instrumentation, and other industries.

This equipment ensures the structural integrity and assembly quality of battery modules and other products through automated high-precision fastening, improving production efficiency and reducing labor costs. It is an essential equipment in related manufacturing industries.

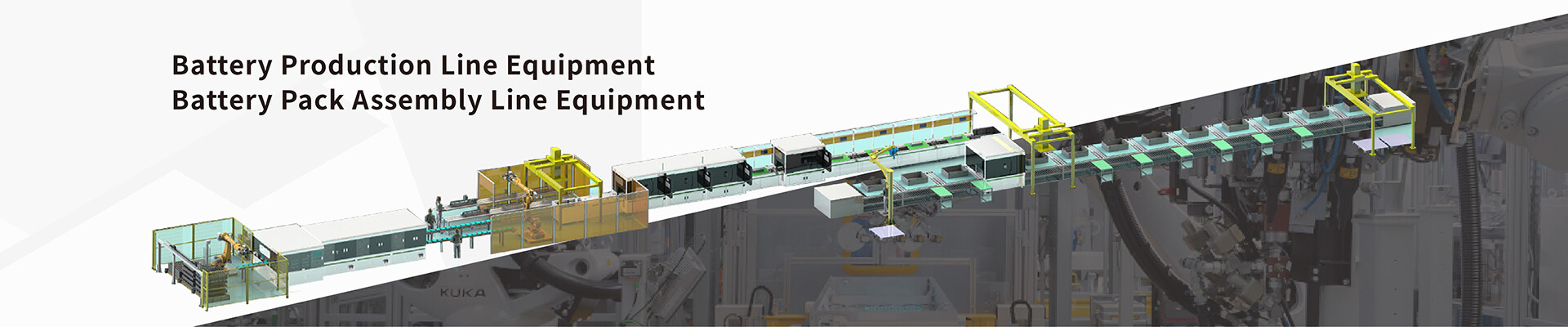

Lithium Battery Intelligent Production Line Solution

Partners

Certificates

Send me a free quote

Related Products

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support