1. One-Stop Service

2. Modular Flexible Design

3. Selectable Automation Levels

4. Intelligent Manufacturing Support

5. Quality Monitoring Assurance

6. High Efficiency and High Productivity

7. Human-Centric Engineering Optimization

8. Safe and Environmentally Friendly Design

9. Technical Training and Maintenance

10. Customized Development

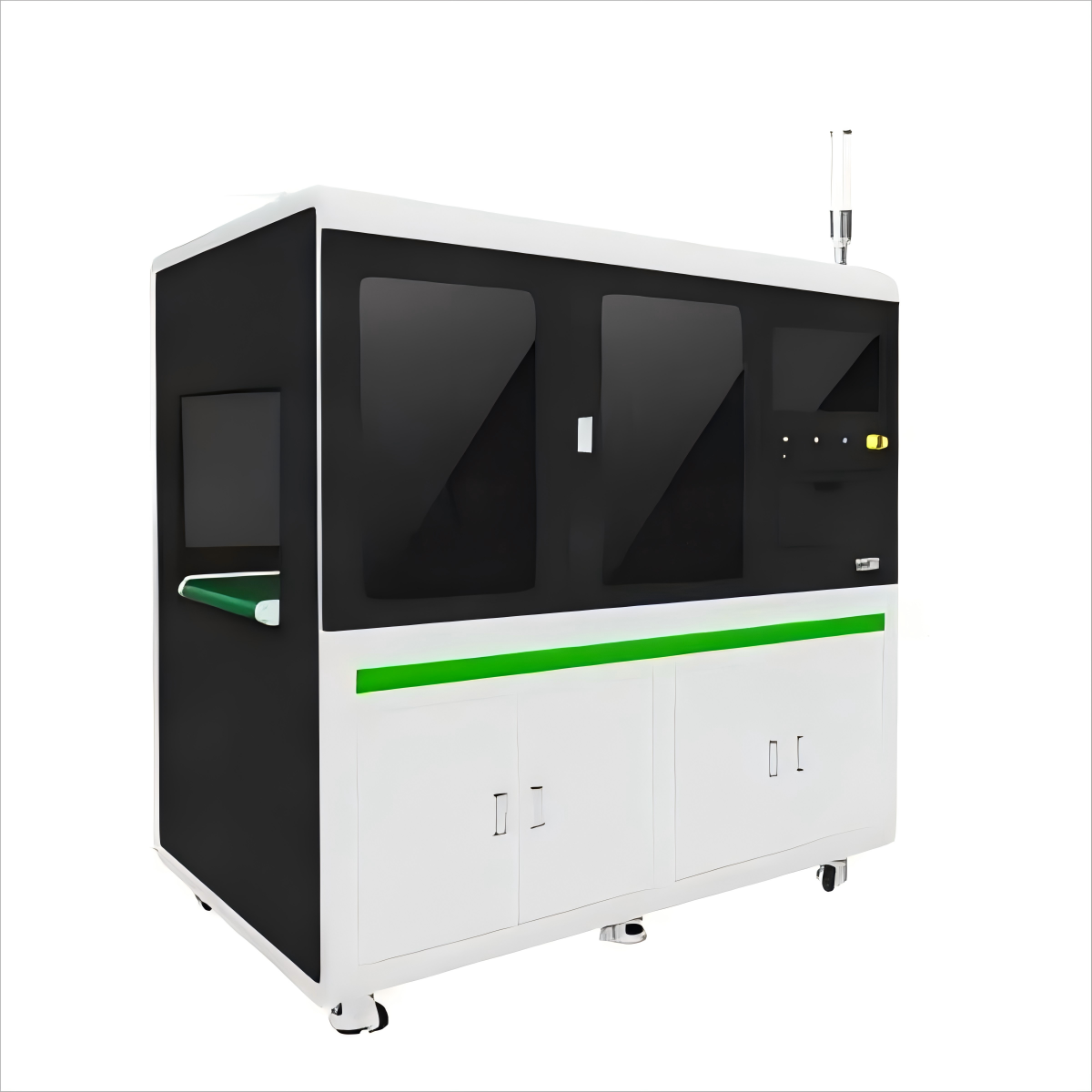

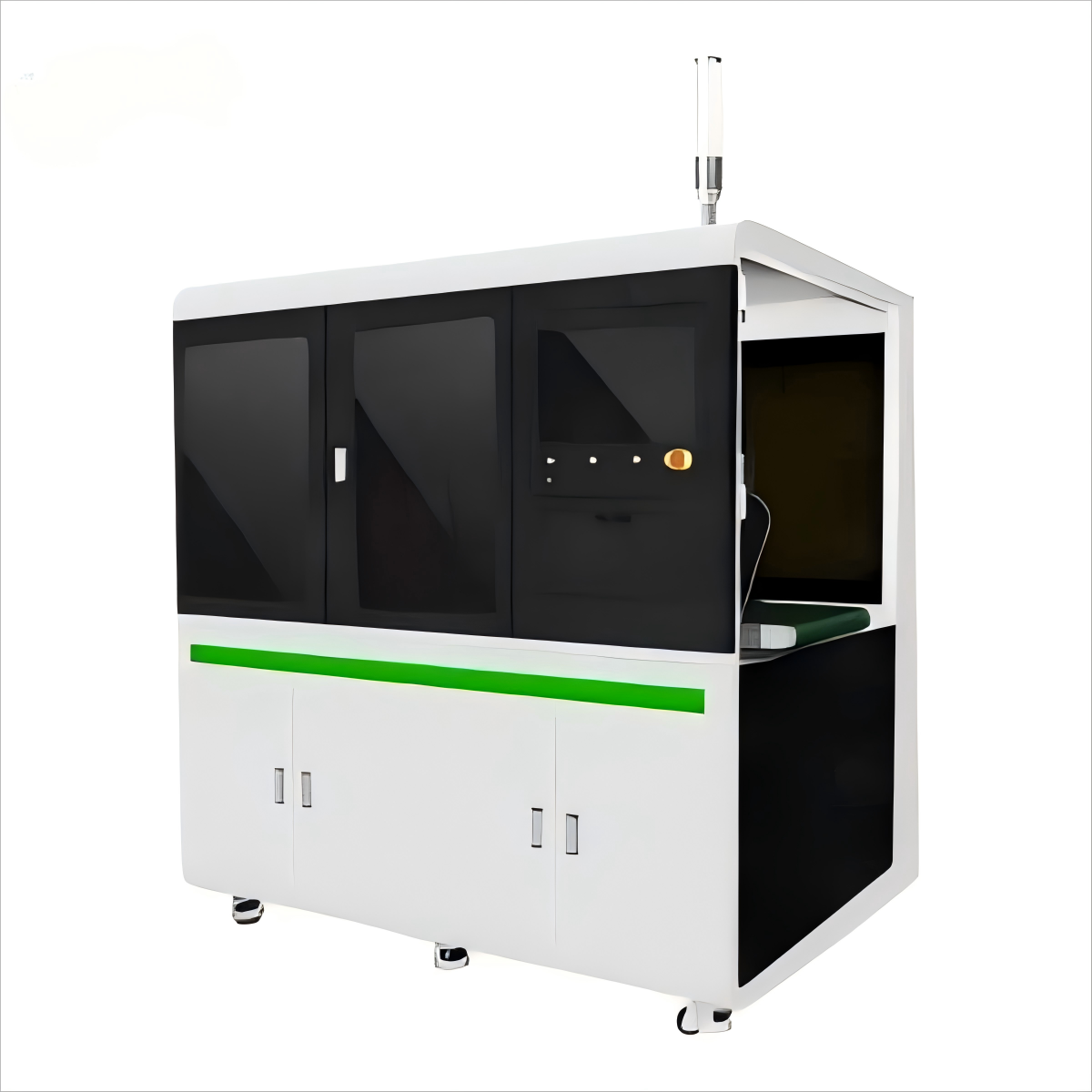

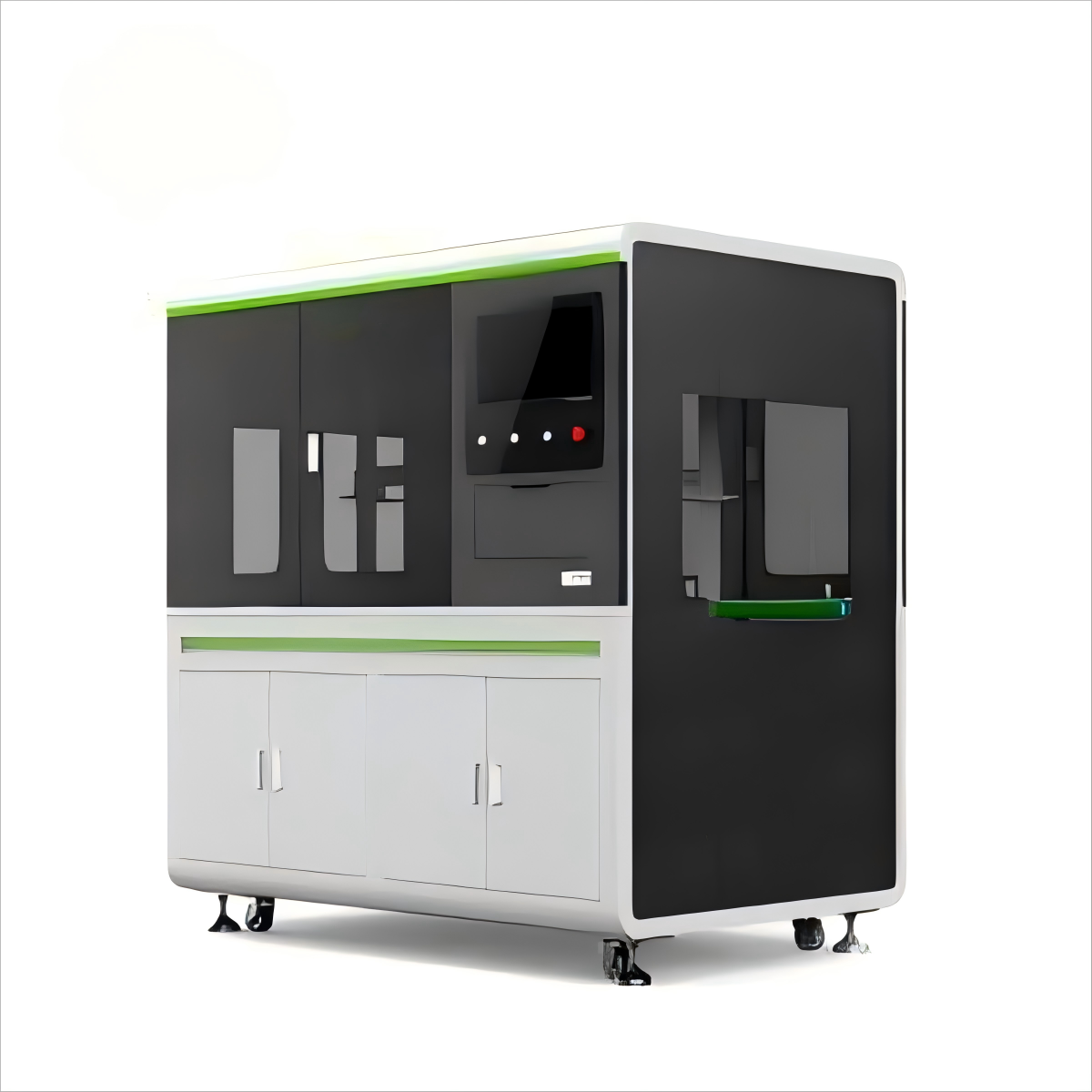

Product Description

1. Keywords:

Vision inspection system, online quality inspection equipment, image processing inspection, weld quality inspection, appearance defect inspection, automated inspection equipment, machine vision.

2. Introduction:

The online vision inspection system utilizes cameras and image processing technology to automatically inspect product weld quality, component positioning, dimensional accuracy, surface defects, and more. By acquiring product images through high-speed cameras and advanced image processing algorithms, it achieves real-time online monitoring and inspection, replacing manual visual inspection and improving inspection efficiency and accuracy. It ensures product quality consistency and reliability, making it an indispensable quality control tool for lithium-ion battery module and pack production lines.

3. Working Process:

The product to be inspected enters the vision inspection area.

High-speed industrial cameras capture images of designated product areas.

Images are transmitted to the image processing unit (industrial PC or embedded system).

Computer vision algorithms process, analyze, detect defects, and measure dimensions from the images.

The system determines if the product passes or fails based on preset standards.

- For failed products, an alarm signal is triggered to remove or stop the production line.

Inspection results and data are recorded and stored for traceability and analysis.

4. Technical Specifications:

- Camera Resolution: 5-20 megapixels.

- Camera Frame Rate: 10-200 fps.

- Lens Focal Length: 8-50mm.

- Light Source Type: LED ring light, line light, backlight, etc.

- Image Processing Unit: Industrial PC, i5/i7 CPU, ≥8GB memory.

- Software System: Based on OpenCV, Halcon, and other vision development platforms.

- Inspection Accuracy: Dimensions ±0.01mm, minimum defect size 0.1mm.

- System Response Time: 0.1-1 second per piece.

5. Technical Features:

- High-precision inspection using high-resolution cameras and high-quality lenses.

- Real-time online inspection for timely defect detection.

- Diverse inspection functions: weld quality, component positioning, appearance defects, dimensional measurement, identification recognition, etc.

- Intelligent algorithms to improve inspection accuracy and robustness.

- High flexibility for rapid changeover of inspection items and parameters.

- User-friendly interface for parameter setting, result display, and data statistics.

- Data recording and traceability for quality control and improvement.

- Industrial-grade design, suitable for production environments, stable and reliable operation.

- Supports integration with automated production lines for coordinated control.

6. Application:

- Lithium-ion battery module and pack production lines: cell welding, module appearance, component installation, dimensional and positional inspection.

- Electronics manufacturing: PCB board, connector, and cable inspection.

- Automotive manufacturing: component dimensional and appearance inspection, assembly line monitoring.

- Pharmaceutical and food: packaging quality inspection.

- Mechanical processing: component appearance and dimensional inspection.

Lithium Battery Intelligent Production Line Solution

Partners

Certificates

Send me a free quote

Related Products

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support