1. One-Stop Service

2. Modular Flexible Design

3. Selectable Automation Levels

4. Intelligent Manufacturing Support

5. Quality Monitoring Assurance

6. High Efficiency and High Productivity

7. Human-Centric Engineering Optimization

8. Safe and Environmentally Friendly Design

9. Technical Training and Maintenance

10. Customized Development

Product Description

1. Keywords:

Vacuum Leak Detection Equipment

Sealing Inspection Equipment

Air Tightness Test Instrument

Vacuum Leak Test

Battery Pack Sealing Performance Inspection

Vacuum Leak Detection Equipment

Leak Test Instrument

Waterproof and Dustproof Inspection

IP Rating Test Equipment

2. Introduction:

Sealing Inspection Equipment is used to test the sealing performance of battery pack enclosures, preventing water vapor, dust, and other substances from entering the battery pack and affecting the battery's performance and safety. The common inspection methods include Air Tightness Test and Vacuum Leak Test. These devices apply a certain pressure or vacuum to the battery pack and detect whether the sealing performance meets the set standards, which are key equipment to ensure the quality and reliability of battery pack products.

Air Tightness Test Instrument Product Introduction:

The Air Tightness Test Instrument applies a certain pressure (positive or negative) to the product under test and monitors the pressure changes over time to determine the sealing performance of the product. It has the advantages of fast detection speed, high accuracy, and easy operation, suitable for quality control in mass production.

Air Tightness Test Instrument .

3. Process Flow:

Product Placement:

Place the battery pack to be tested inside the airtight chamber of the Air Tightness Test Instrument, ensuring accurate placement and good sealing.Fixture Sealing:

Activate the clamping fixture using a cylinder or mechanical device to seal the battery pack, preventing leakage during the test.Pressure Application:

Apply the set air pressure (positive or negative) to the interior (or exterior) of the battery pack, reaching the test pressure value.Pressure Stabilization:

Maintain the pressure for a period of time to stabilize the test pressure, eliminating temperature and pressure fluctuations within the system.Test Phase:

Record the pressure change (ΔP) within the set time, and determine the sealing performance of the product based on the pressure decay.Result Judgment:

Determine whether the product meets the preset pass criteria.Test Completion:

Release the pressure, open the fixture, and remove the tested product.

4. Technical Specifications:

- Test Pressure Range: Positive 0-500kPa, Negative -100kPa-0.

- Pressure Resolution: 0.1-1Pa.

- Test Accuracy: ±0.1% FS.

- Test Time: 1-999s.

- Leak Detection Accuracy: 1×10⁻³ Pa·m³/s.

- Display and Control: ≥7-inch color touchscreen, PLC or industrial PC control.

- Data Storage and Communication: ≥100,000 records, Ethernet/USB/RS232.

5. Technical Features:

- High-Precision Detection.

- Fast Detection.

- Multiple Test Modes.

- Programmable Testing.

- Data Recording and Traceability.

- Easy Operation.

- High Safety.

6. Application Areas:

- Lithium-ion Battery Pack Production.

- Automotive Manufacturing.

- Electronic Product Manufacturing.

- Home Appliance Manufacturing.

- Food and Pharmaceutical Packaging

- Other Areas Requiring Sealing Performance Inspection.

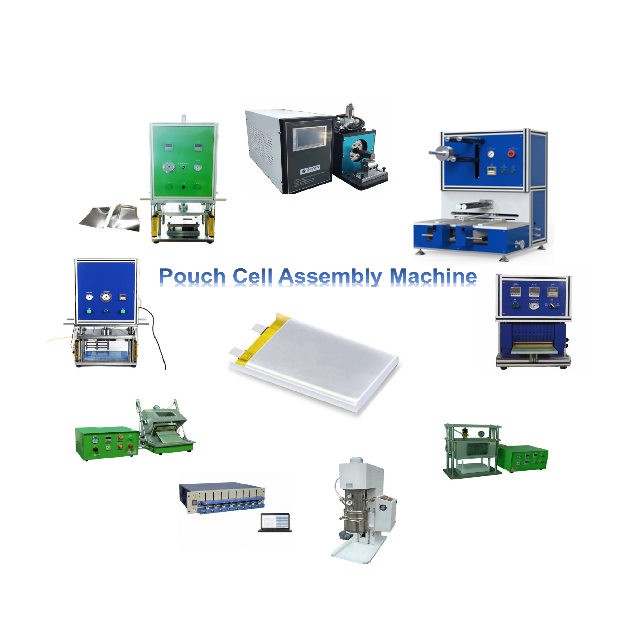

Lithium Battery Intelligent Production Line Solution

Partners

Certificates

Send me a free quote

Related Products

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support