1. One-Stop Service

2. Modular Flexible Design

3. Selectable Automation Levels

4. Intelligent Manufacturing Support

5. Quality Monitoring Assurance

6. High Efficiency and High Productivity

7. Human-Centric Engineering Optimization

8. Safe and Environmentally Friendly Design

9. Technical Training and Maintenance

10. Customized Development

Product Description

1:Keywords:

Lithium Battery Packaging Equipment

Cell Wrapping Machine

Battery Packaging Machine

Battery Sealing Equipment

2: Introduction:

The cell packaging machine is a crucial piece of equipment in lithium battery production, used to package and seal cells to ensure their integrity. The machine typically uses heat sealing or vacuum packaging technology to effectively seal the cell, preventing electrolyte leakage or air intrusion, which enhances the battery's safety and extends its lifespan. The packaging machine is suitable for various battery shapes, including prismatic, cylindrical, and pouch cells.

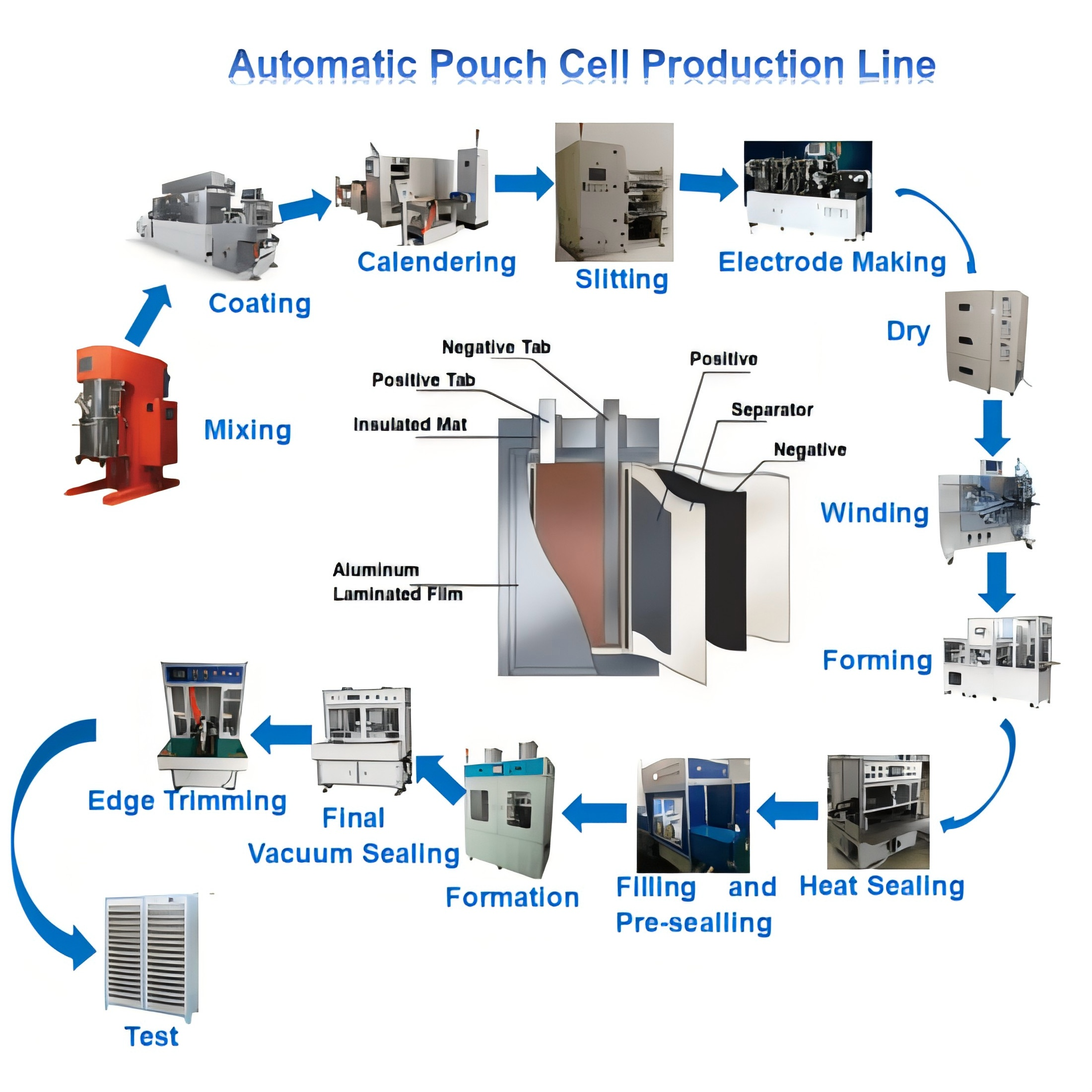

3: Process Flow:

Cell Feeding: Cells are automatically fed into the packaging machine through an automated feeding system.

Packaging Material Feeding: Packaging materials are automatically conveyed to the sealing area.

Sealing Operation: The machine seals the cells using heat sealing or vacuum packaging technology.

Sealing Quality Inspection: The system automatically checks the sealing quality to ensure a leak-proof seal.

Product Output: The sealed cells are automatically discharged for further processing.

4: Technical Specifications:

Packaging Speed: 50-150 cells/hour

Sealing Method: Heat sealing, vacuum packaging

Maximum Packaging Size: 200 mm x 300 mm

Sealing Precision: ±0.1 mm

Power Consumption: 3 kW - 10 kW

Control System: PLC control, touchscreen operation

5: Technical Features:

High Seal Integrity: Uses vacuum packaging technology to ensure no air remains inside the cell, enhancing battery safety.

Efficient Packaging: Automated operation improves packaging efficiency and ensures consistent sealing quality.

Multiple Sealing Methods: Supports both heat sealing and vacuum packaging to accommodate different battery types.

Automatic Inspection: Equipped with a sealing quality inspection system to monitor the sealing effect in real-time, ensuring high-quality packaging for each cell.

Safety Assurance: Features overload protection and temperature monitoring to ensure safe operation during the sealing process.

6: Application:

Lithium-ion Battery Manufacturing

Power Battery Production

Energy Storage Battery Production

Lithium Battery Intelligent Production Line Solution

Partners

Certificates

Send me a free quote

Related Products

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support