1. One-Stop Service

2. Modular Flexible Design

3. Selectable Automation Levels

4. Intelligent Manufacturing Support

5. Quality Monitoring Assurance

6. High Efficiency and High Productivity

7. Human-Centric Engineering Optimization

8. Safe and Environmentally Friendly Design

9. Technical Training and Maintenance

10. Customized Development

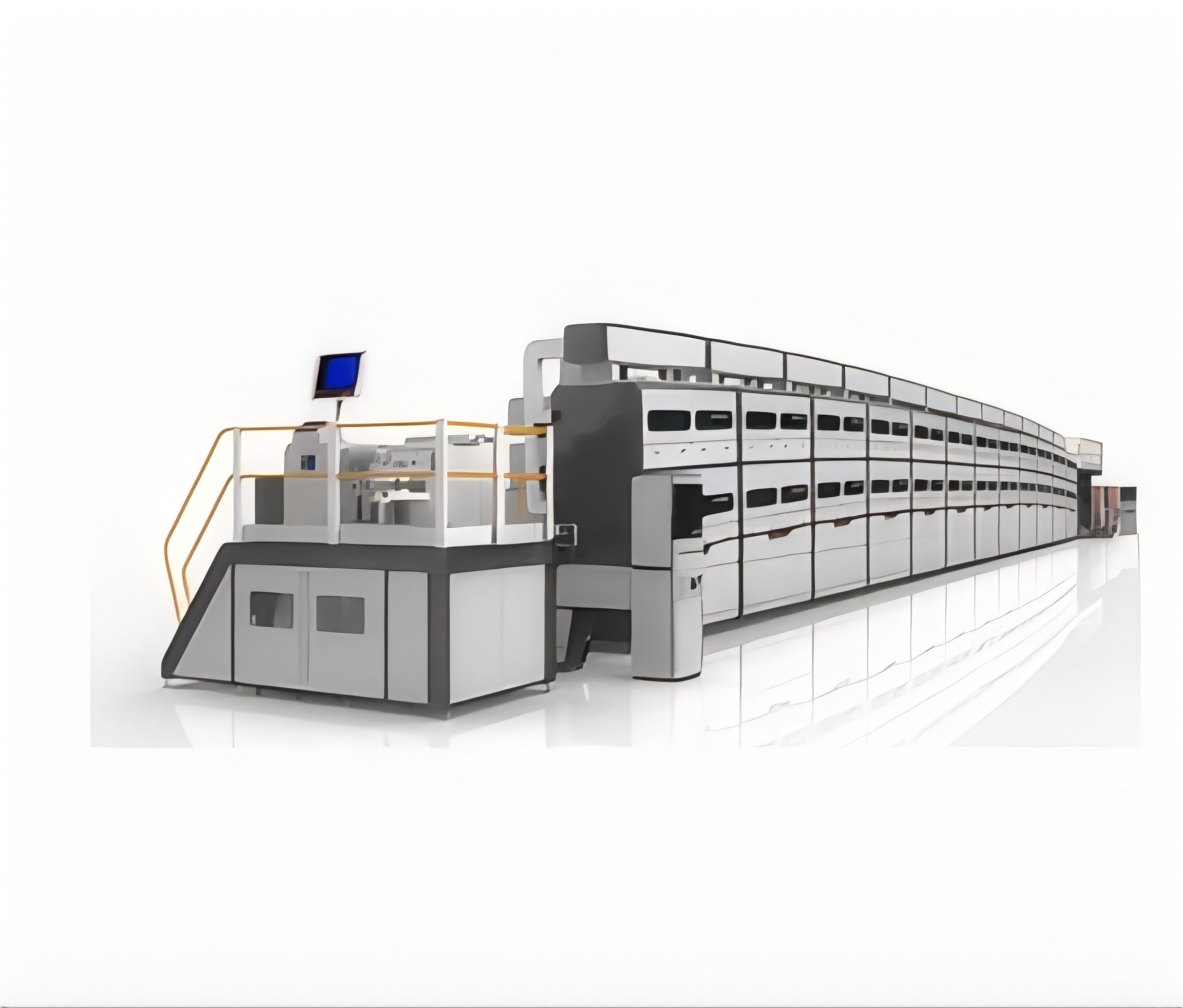

Product Description

1: Keywords:

Intermittent Coating

Continuous Coating

Lithium Battery Electrode Coating Equipment

Precision Coating Machine

Roll-to-Roll Coating Machine

2: Introduction:

Intermittent and continuous coating machines are essential equipment used to uniformly coat cathode and anode slurries onto current collectors (aluminum foil for cathodes and copper foil for anodes) to form electrode sheets. Intermittent coating is suitable for electrode manufacturing that requires leaving space for electrode tabs, while continuous coating is used for full-width coating. The equipment can achieve high-precision and high-speed coating according to process requirements, ensuring consistency in thickness and weight of the electrode sheets.

3: Process Flow:

Slurry Preparation: Prepared cathode and anode slurries are placed into the coating machine's feeding system.

Substrate Winding: The current collector (aluminum or copper foil) is installed on the unwinding device, ready for coating.

Coating Process:

Intermittent Coating: Intermittent coating is performed according to the set coating length and intervals, leaving space for electrode tabs.

Continuous Coating: Continuous coating is performed on the entire substrate without intervals.

Coating Control: The coating thickness is controlled by adjusting the gap between the doctor blade or coating head.

Drying Entry: The coated electrode sheet enters the drying equipment for solvent evaporation.

4: Technical Specifications:

Coating Width: 300 mm - 1600 mm (customizable)

Coating Speed: 1 m/min - 100 m/min

Coating Thickness: 0.005 mm - 0.2 mm

Coating Precision: ±2 μm

Substrate Tension Control: 5 N - 50 N

Applicable Slurry Viscosity: 5000 - 20,000 cps

Power Requirements: AC 380V, 50Hz

5: Technical Features:

High-Precision Coating: Utilizes precise coating mechanisms to ensure uniformity and consistency of coating thickness.

High Flexibility: Can switch between intermittent and continuous coating modes to adapt to different process requirements.

Tension Control System: Accurately controls substrate tension to prevent wrinkles and misalignment.

High Automation: Equipped with PLC and touch screen control for automated operation and parameter setting.

Safe and Reliable: Features explosion-proof design and safety protection measures to ensure operator and equipment safety.

Easy Maintenance: Modular design for easy cleaning and replacement of coating components.

6: Application:

Lithium-ion Battery Industry: Manufacturing of cathode and anode electrode sheets.

Supercapacitors: Coating of electrode materials.

Electronic Materials: Coating of conductive films and functional thin films.

New Energy Materials: Coating of fuel cell electrodes and solar cell materials.

Lithium Battery Intelligent Production Line Solution

Partners

Certificates

Send me a free quote

Related Products

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support