1. One-Stop Service

2. Modular Flexible Design

3. Selectable Automation Levels

4. Intelligent Manufacturing Support

5. Quality Monitoring Assurance

6. High Efficiency and High Productivity

7. Human-Centric Engineering Optimization

8. Safe and Environmentally Friendly Design

9. Technical Training and Maintenance

10. Customized Development

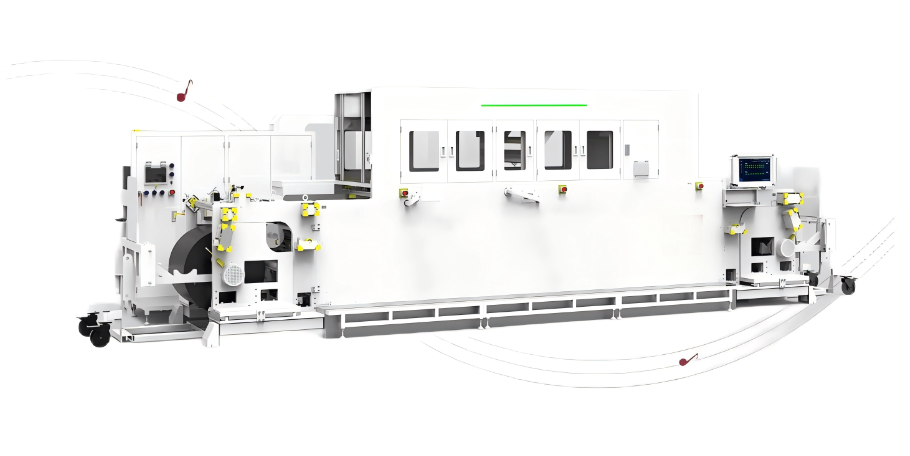

Product Description

1: Keywords:

- Electrostatic Dust Removal Equipment

- Electrode Plate Dust Remover

- Lithium Battery Electrode Cleaning Equipment

- Electrostatic Dust Adsorption

- Electrode Surface Cleaning Machine

2: Introduction:

The electrostatic dust remover is a device that uses the principle of electrostatic adsorption to remove dust and fine particles from the surface of electrode plates. Through the high-voltage electrostatic field generated by the electrostatic device, particles on the surface of the electrode plates are charged and subsequently absorbed into the dust collection system. The electrostatic dust remover features non-contact cleaning, surface protection, and high dust removal efficiency. It effectively enhances the cleanliness of electrode plates, ensuring the quality of subsequent processes and the performance of batteries.

3: Process Flow:

- Electrode Plate Feeding: The electrode plates that need cleaning are fed into the dust remover via a conveyor system.

- Electrostatic Charging: The plates pass through the electrostatic charging zone where surface particles become charged.

- Adsorption and Dust Removal: Charged particles are attracted and absorbed by the dust collection roller or suction device.

- Dust Collection and Treatment: Collected dust is processed centrally to prevent secondary pollution.

- Electrode Plate Output: The cleaned plates are discharged and proceed to the next step in the production process.

4: Technical Specifications:

- Applicable Electrode Plate Width: 200 mm - 1600 mm

- Conveyor Speed: 5 m/min - 50 m/min

- Dust Removal Efficiency: ≥99%

- Electrostatic Voltage: ±5 kV - ±50 kV (adjustable)

- Power Consumption: 2 kW - 10 kW

- Electrostatic Mode: AC Electrostatic, DC Electrostatic

- Control System: PLC Control, Touchscreen Operation

- Power Requirements: AC 220V or 380V, 50Hz

5: Technical Features:

- Non-Contact Cleaning: Uses electrostatic adsorption, eliminating the need for physical contact and preventing damage to the electrode surface.

- High-Efficiency Dust Removal: Efficiently removes dust and particles down to sub-micron levels, improving electrode plate cleanliness.

- Double-Sided Cleaning: Capable of cleaning both sides of the electrode plates simultaneously, enhancing operational efficiency.

- Automated Operation: Equipped with an intelligent control system with adjustable parameters for easy and convenient operation.

- Safe and Reliable: Features static discharge and overvoltage protection to ensure the safety of both the equipment and operators.

- Dust Collection System: Comes with a high-efficiency filter to prevent dust leakage and safeguard the environment.

6: Application:

- Lithium-ion Battery Manufacturing: For cleaning positive and negative electrode plates before winding or stacking processes.

- Electronics Manufacturing: Surface dust removal for PCB boards, flexible circuit boards, etc.

- Optoelectronic Materials: Surface cleaning of display screens, optical films, and similar materials.

- Precision Coating: Surface treatment before coating for automotive and electronic product casings.

Lithium Battery Intelligent Production Line Solution

Partners

Certificates

Send me a free quote

Related Products

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support