1. One-Stop Service

2. Modular Flexible Design

3. Selectable Automation Levels

4. Intelligent Manufacturing Support

5. Quality Monitoring Assurance

6. High Efficiency and High Productivity

7. Human-Centric Engineering Optimization

8. Safe and Environmentally Friendly Design

9. Technical Training and Maintenance

10. Customized Development

Product Description

1: Keywords:

18650 Battery Production Line

21700 Battery Production Equipment

Cylindrical Battery Manufacturing Process

Lithium-ion Battery Production Equipment

Power Tool Battery Production Line

2:Introduction:

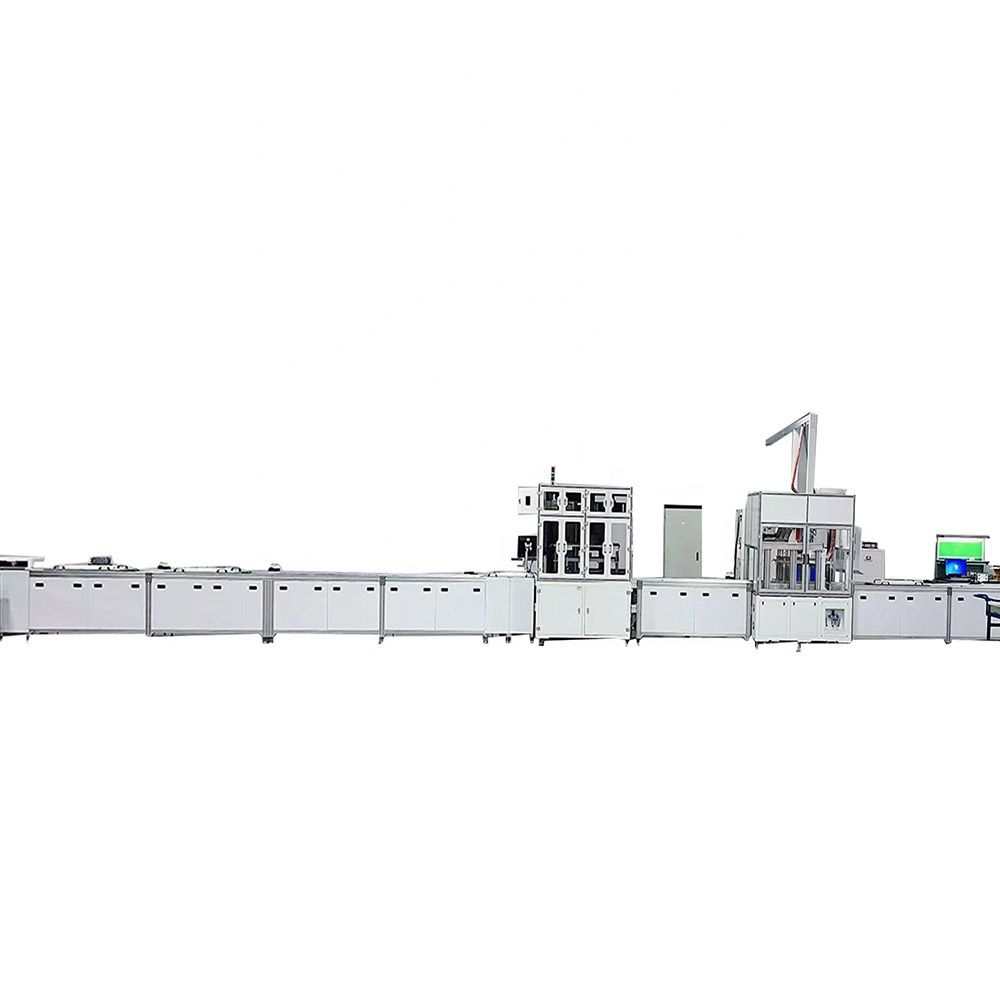

The cylindrical lithium battery production line is designed for manufacturing 18650, 21700, and other models of cylindrical lithium-ion batteries. This production line covers the entire process from electrode manufacturing, cell assembly, formation and grading, to testing and packaging, featuring a high level of standardization and automation. The production line has mature technology, high efficiency, stable quality, and can meet large-scale production demands.

2:Process Flow:

Slurry Preparation (Mixing)

Mix active materials, conductive agents, binders, and solvents according to the formula ratio to prepare uniform electrode slurries for both positive and negative electrodes.

Coating

Use coating machines to evenly apply positive and negative electrode slurries onto aluminum foil (positive) and copper foil (negative) to form electrode sheets.

Drying

Dry the coated electrode sheets in drying ovens to remove solvents and ensure the quality and performance of the electrodes.

Calendering (Rolling)

Compress the dried electrode sheets to achieve the required thickness and density, enhancing battery performance.

Slitting

Cut the calendered electrode sheets to the designed size, obtaining electrode strips suitable for winding.

Winding

Wind the positive electrode, separator, and negative electrode in a specified order and tension on a winding machine to form the cell core.

Assembly

Insert the wound cell core into a metal casing, weld current collectors and cap, and install safety components.

Electrolyte Filling

Inject electrolyte into the cell under vacuum conditions to ensure thorough electrode wetting.

Sealing

Seal the battery after electrolyte filling, typically using laser welding or crimping methods.

Formation and Grading

Perform initial charge-discharge cycles (formation) to activate battery materials, followed by capacity testing and sorting.

Testing and Packaging

Conduct electrical performance tests and visual inspections. Package qualified products for storage.

3:Technical Specifications:

Applicable Battery Models: 18650, 21700, 26650, etc.

Production Speed: 30-60 cells per minute (depending on equipment configuration).

Automation Level: Fully automated production line .

Production Yield:≥98%.

Floor Space: Approximately 500-1000 square meters (depending on capacity).

Power Requirements: Three-phase AC 380V, 50Hz.

Equipment Power: About 200-500kW (depending on equipment quantity and models).

4: Technical Features:

High Standardization: Adopts international standard cylindrical battery specifications, strong equipment compatibility and versatility.

Mature Technology: Production process technology matured through years of development, high production stability.

High Automation: Key processes use fully automated equipment, reducing human error and improving production efficiency and product consistency.

Strict Quality Control: Equipped with online inspection systems, real-time monitoring of key process parameters to ensure product quality.

High Flexibility: Production line can be adjusted to accommodate different battery model production.

Easy Maintenance: Modular equipment design for convenient maintenance and upgrades.

5: Application:

Power Tools: Such as electric drills, saws, garden tools, etc., requiring high power and durability.

Laptops and Digital Products: Providing reliable power sources for laptops, digital cameras, etc.

Electric Bicycles/Scooters: Powering small electric vehicles, requiring high energy density and longevity.

Energy Storage Systems: Home and small commercial energy storage systems, balancing energy supply and demand.

Medical Equipment: Portable medical devices such as ECG monitors.

Lithium Battery Intelligent Production Line Solution

Partners

Certificates

Send me a free quote

Related Products

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support