1. One-Stop Service

2. Modular Flexible Design

3. Selectable Automation Levels

4. Intelligent Manufacturing Support

5. Quality Monitoring Assurance

6. High Efficiency and High Productivity

7. Human-Centric Engineering Optimization

8. Safe and Environmentally Friendly Design

9. Technical Training and Maintenance

10. Customized Development

Product Description

1: Keywords:

Polymer Lithium Battery Production Equipment

Soft Pack Battery Manufacturing Process

Customizable Shape Battery Production Line

Thin and Light Battery Production Equipment

Consumer Electronics Battery Manufacturing

2: Introduction:

The soft pack battery production line primarily manufactures polymer soft pack lithium-ion batteries, using aluminum-plastic composite film as the outer packaging. This production line can produce lightweight, high energy density, and customizable shape batteries, meeting the high-performance and personalized requirements of consumer electronics and high-end equipment.

3: Process Flow:

Slurry Preparation (Mixing)

Prepare positive and negative electrode slurries, requiring good uniformity and stability.

Coating

Apply slurry onto current collectors using precision coating technology to form ultra-thin electrode sheets.

Drying and Calendering

Dry to remove solvents, and calendar to adjust electrode thickness, achieving high energy density.

Slitting

Precisely cut electrode sheets according to design dimensions, preparing for stacking.

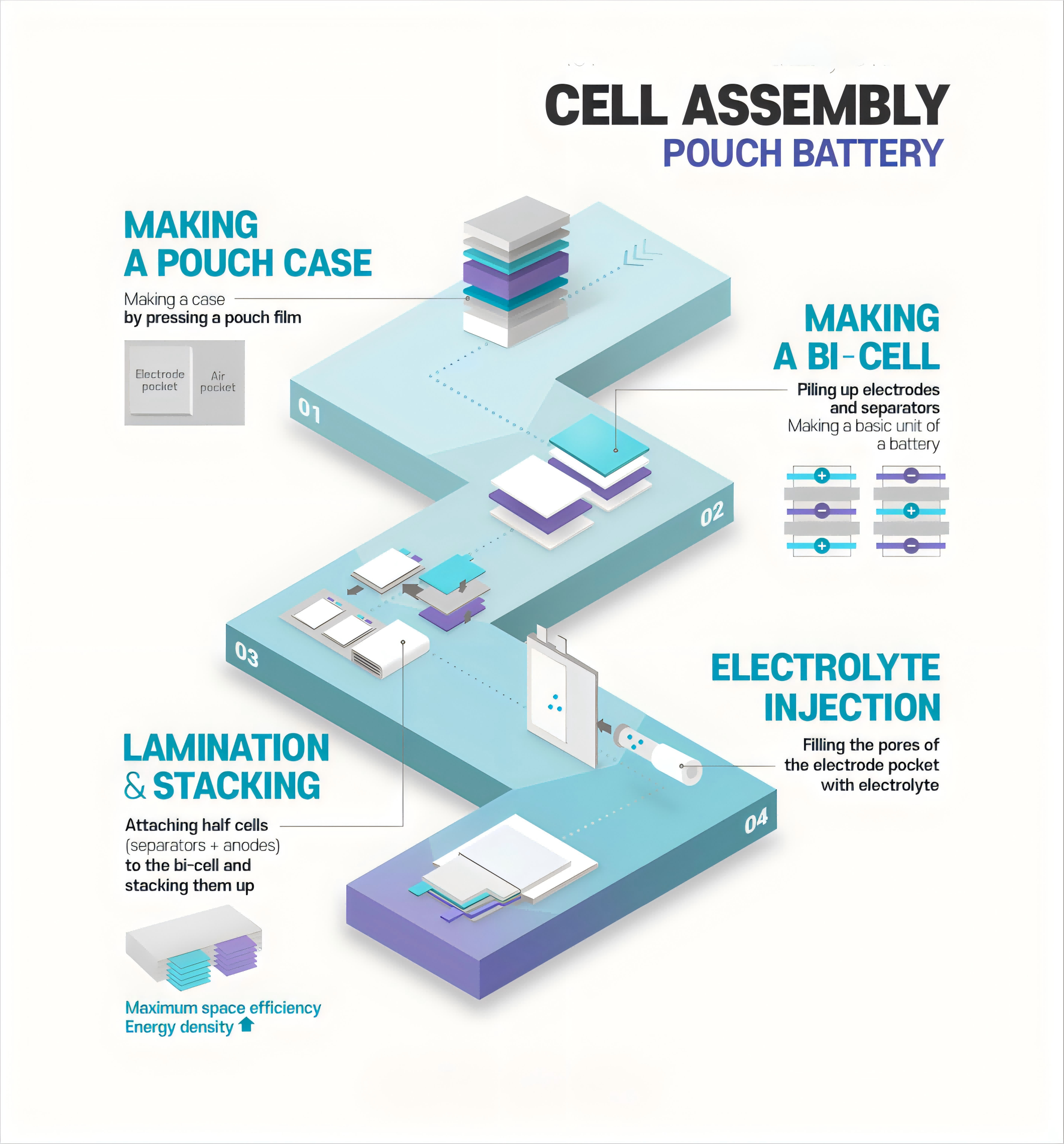

Stacking

Stack positive electrodes, separators, and negative electrodes in sequence to form the cell core.

Assembly

Place the cell core in aluminum-plastic film and perform heat sealing to form a closed battery casing.

Electrolyte Filling

Inject electrolyte under vacuum conditions, ensuring thorough wetting of the cell core.

Sealing

Seal the electrolyte filling port using heat sealing technology to ensure battery airtightness.

Formation and Grading

Perform formation to activate electrochemical properties, followed by capacity grading tests.

Testing and Packaging

Conduct electrical performance tests and visual inspections. Package qualified products for shipment.

3: Technical Specifications:

Applicable Battery Sizes: Customizable, e.g., 500mAh, 1000mAh, 5000mAh, etc.

Production Speed: 20-50 cells per minute.

Automation Level: Automated or semi-automated .

Production Yield: ≥97%.

Floor Space: Approximately 800-1500 square meters.

Power Requirements: Three-phase AC 380V, 50Hz.

Equipment Power: About 300-800kW.

4: Technical Features:

Lightweight and Thin: Using aluminum-plastic film reduces overall battery weight, more suitable for portable devices.

Customizable Shape: Can produce batteries of different shapes and sizes according to product design requirements.

High Energy Density: Thinner packaging materials allow for higher volumetric energy density.

Superior Safety Performance: Soft pack batteries are less prone to metal short circuits when mechanically damaged, enhancing safety.

Flexible Process: Production line can be quickly adjusted to adapt to new product development and small-batch production.

Good Sealing Performance: Advanced packaging technology prevents electrolyte leakage, extending battery life.

5: Application:

Smartphones and Tablets: Provide high-performance batteries for electronic products pursuing thin and light designs.

Drones and Model Aircraft: Require high energy density and lightweight batteries.

Wearable Devices: Such as smartwatches and fitness bands, requiring miniaturized batteries.

Bluetooth Devices and Wireless Earphones: Small size, lightweight, long battery life.

Medical Devices: Portable medical equipment such as insulin pumps and heart rate monitors.

Lithium Battery Intelligent Production Line Solution

Partners

Certificates

Send me a free quote

Related Products

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support