1. One-Stop Service

2. Modular Flexible Design

3. Selectable Automation Levels

4. Intelligent Manufacturing Support

5. Quality Monitoring Assurance

6. High Efficiency and High Productivity

7. Human-Centric Engineering Optimization

8. Safe and Environmentally Friendly Design

9. Technical Training and Maintenance

10. Customized Development

Product Description

1: Keywords:

Prismatic Aluminum Shell Battery Production Line

Power Battery Manufacturing Equipment

High Energy Density Battery Production

Electric Vehicle Battery Production Line

Energy Storage Battery Manufacturing Process

2: Introduction:

The prismatic lithium battery production line is used to manufacture metal-cased prismatic lithium-ion batteries, primarily for electric vehicles and energy storage systems. This production line emphasizes high energy density and structural stability, employing advanced stacking or winding processes. The produced batteries feature good consistency and long cycle life, meeting the demands of high-end markets.

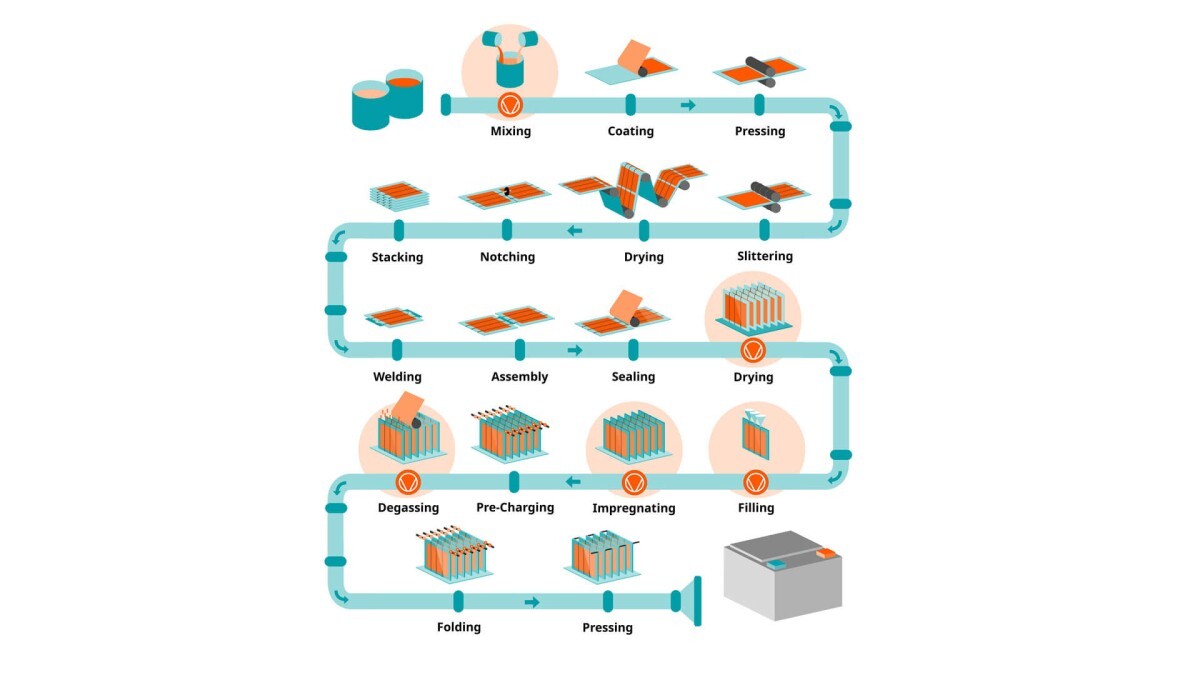

3: Process Flow:

Slurry Preparation (Mixing)

Prepare high-quality positive and negative electrode slurries, ensuring uniform distribution of active materials.

Coating

Use precision coating equipment to evenly apply slurry onto current collectors, forming electrode sheets.

Drying and Calendering

Dry to remove solvents, and calendar to adjust electrode thickness and density, improving battery performance.

Slitting

Precisely cut electrode sheets to designed sizes, preparing for stacking or winding processes.

Stacking or Winding

Stacking process: Layer positive electrodes, separators, and negative electrodes in sequence to form the cell core.

Winding process: Wind electrode sheets into a flat spiral cell core.

Assembly

Insert the cell core into a prismatic metal casing, weld tabs, and install safety units such as explosion-proof valves.

Electrolyte Filling

Inject electrolyte into the cell in a clean environment, ensuring consistency.

Sealing

Seal the battery using laser welding or riveting methods to ensure airtightness.

Formation and Grading

Perform formation and capacity testing to screen qualified products.

Testing and Packaging

Conduct electrical, mechanical, and safety performance tests. Package qualified products for shipment.

4: Technical Specifications:

Applicable Battery Sizes: Customizable, e.g., 100Ah, 200Ah, etc.

Production Speed: 10-30 cells per minute (depending on battery size and equipment configuration).

Automation Level: Highly automated production line.

Production Yield: ≥98%.

Floor Space: Approximately 1000-2000 square meters.

Power Requirements: Three-phase AC 380V, 50Hz.

Equipment Power: About 500-1000kW.

5: Technical Features:

High Energy Density: Optimize materials and processes to increase battery energy density, extending equipment operation time.

Strong Structural Stability: Prismatic metal casing provides good mechanical support, resistant to impact and vibration.

Advanced Manufacturing Process: Employ stacking or winding processes to improve battery consistency and reliability.

Strict Quality Management: Full-process quality monitoring, meeting automotive and energy storage quality standards.

Excellent Safety Performance: Equipped with multiple safety designs to prevent overcharging, over-discharging, short circuits, and other risks.

Customizable Production: Customize batteries of different specifications and capacities according to customer requirements.

6:Application:

Electric Vehicles (EVs): Provide power batteries for pure electric, hybrid, and plug-in hybrid vehicles.

Large-scale Energy Storage Systems: Used for grid peak shaving, frequency regulation, and renewable energy storage, such as wind and solar power.

Communication Base Station Backup Power: Ensure normal operation of communication networks during power outages.

Home and Commercial Energy Storage: Provide energy management solutions in conjunction with photovoltaic power generation.

Rail Transit and Ships: Supply power for electrically driven trains and ships.

Lithium Battery Intelligent Production Line Solution

Partners

Certificates

Send me a free quote

Related Products

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support