1. One-Stop Service

2. Modular Flexible Design

3. Selectable Automation Levels

4. Intelligent Manufacturing Support

5. Quality Monitoring Assurance

6. High Efficiency and High Productivity

7. Human-Centric Engineering Optimization

8. Safe and Environmentally Friendly Design

9. Technical Training and Maintenance

10. Customized Development

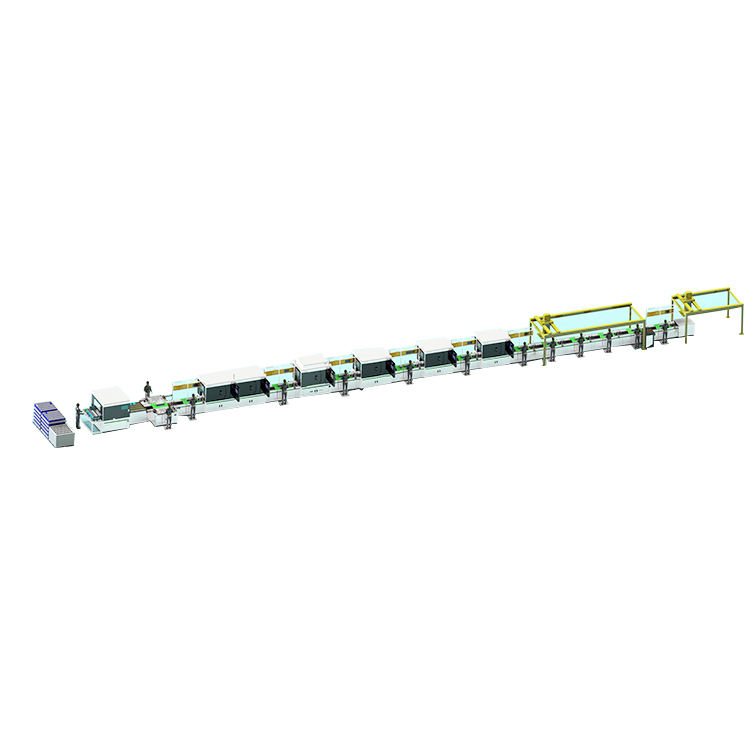

Product Description

Lithium battery assembly, Automated production line, Battery pack manufacturing, New energy battery, Industry 4.0, Smart manufacturing, High-precision automation.

2: Introduction:

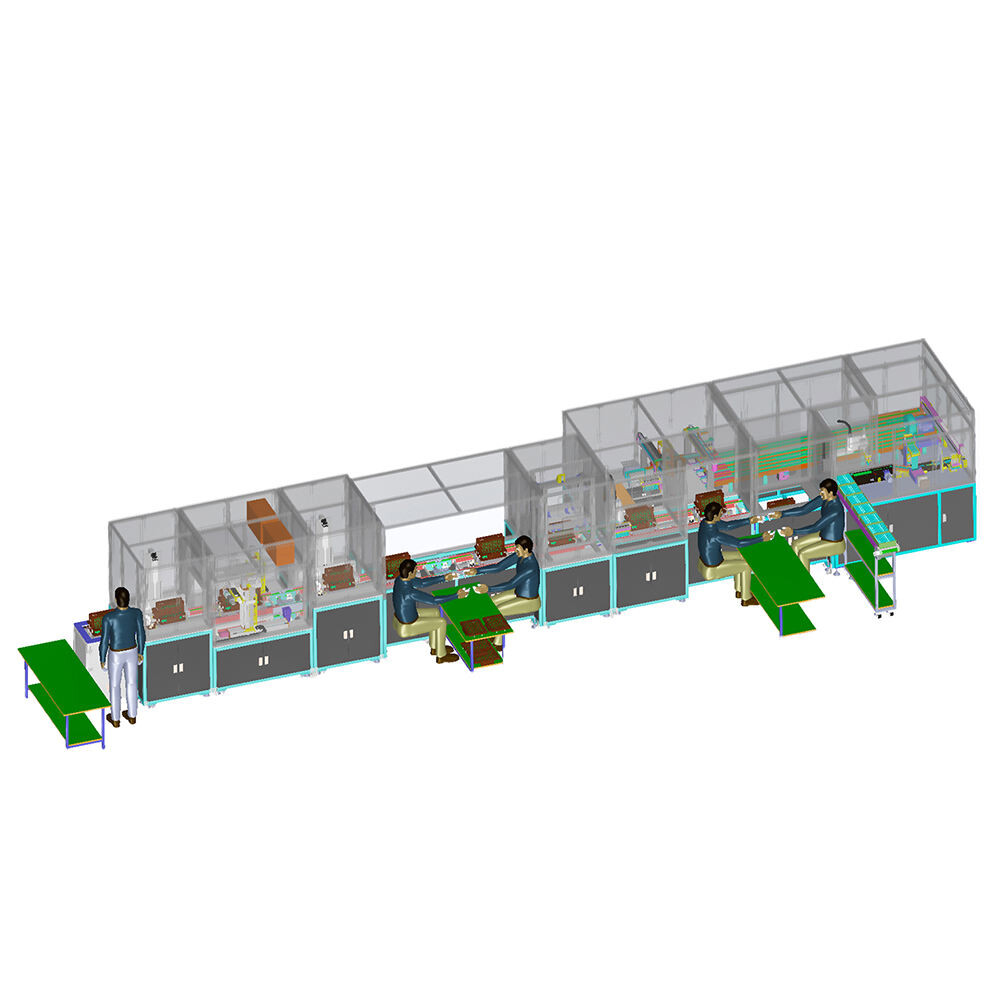

This state-of-the-art production line achieves seamless automated battery pack production. Spanning an impressive 16 meters, it integrates cutting-edge technology through the following equipment.

Precision battery feeding and paper pad placement station.

AI-driven automatic sorting based on comprehensive battery loading test data.

High-speed robotic battery assembly with multi-axis precision control.

Advanced battery pack nickel welding station with real-time quality monitoring.

Precision BMS PCB soldering station with temperature and pressure control.

Intelligent battery pack finished product handling and packaging system.

3: Technical Parameters:

Total production line length: 16 meters.

Production capacity: Up to X battery packs per hour (customizable).

Precision level: ±0.1mm positioning accuracy.

Processing efficiency: 99.5% uptime.

Product quality consistency: >99.9%.

Operational safety: Advanced multi-level safety protocols.

Data acquisition: Real-time, full process monitoring with 1000+ data points.

Information integration level: High, achieving seamless information interaction between production planning, execution, and control layers.

Energy consumption: 30% lower than industry standard.

Adaptability: Capable of handling multiple battery types (18650, 21700, prismatic, pouch).

4: Technical Features:

Industry 4.0 compliant fully automated operation, dramatically improving production efficiency.

Advanced integrated CCD vision identification system ensuring micron-level accuracy.

AI-powered automatic feeding and sorting mechanism, guaranteeing optimal cell consistency.

Real-time automatic barcode scanning and binding, enabling comprehensive product lifecycle traceability.

Seamless integration with MES and ERP systems, facilitating complete recording and analysis of product manufacturing data.

State-of-the-art robotics replacing traditional manual operations, ensuring unparalleled product quality stability.

Modular design allowing independent operation of each equipment, with user-friendly interfaces for easy operation and maintenance.

Remote monitoring and predictive maintenance capabilities.

Energy-efficient design with power management system.

Flexible production capabilities, accommodating various battery sizes and configurations.

5: Additional Features:

• Customizable production modules to meet specific client needs

• Virtual reality (VR) based operator training system

• Digital twin technology for real-time process optimization

• Green manufacturing practices with minimal environmental impact

• 24/7 global technical support and remote diagnostics

6: Application:

• New energy vehicles (EVs, HEVs, PHEVs).

• High-performance portable electronic devices.

• Grid-scale and residential energy storage systems.

• Aerospace and marine applications.

• Industrial power tools and equipment.

Lithium Battery Intelligent Production Line Solution

Partners

Certificates

Send me a free quote

Related Products

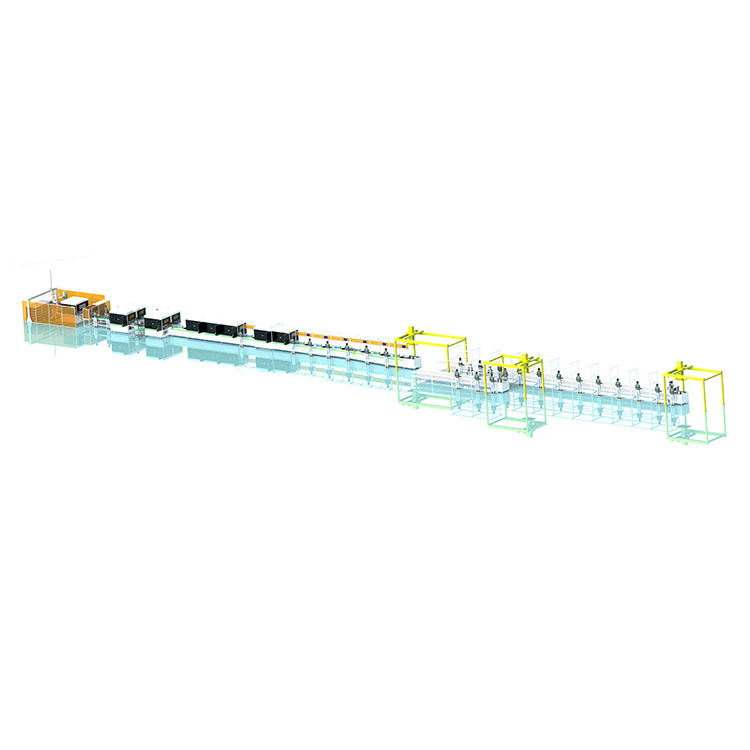

Industrial and Commercial Energy Storage Module Laser Production LineThis automated assembly line consists of three main sections: cell sorting, module line, and PACK assembly. It includes processes such as cell sorting, OCV testing, laser engraving, polarity detection, pole cleaning, bus line installation, laser welding, and pressure resistance testing.

Industrial and Commercial Energy Storage Module Laser Production LineThis automated assembly line consists of three main sections: cell sorting, module line, and PACK assembly. It includes processes such as cell sorting, OCV testing, laser engraving, polarity detection, pole cleaning, bus line installation, laser welding, and pressure resistance testing. Battery Pack Automated Assembly Production LineThis production line is suitable for over 90% of cylindrical products in the market, with a high degree of standardization. Main processes include manual feeding, OCV sorting and scanning, secondary scanning, manual insertion into brackets, AI polarity detection, NG station, A-side laser welding, automatic fixture plate flipping, B-side laser welding, and manual fixture disassembly. It features a unique double-sided cross spot welding equipment, achieving one-time welding without flipping or moving.

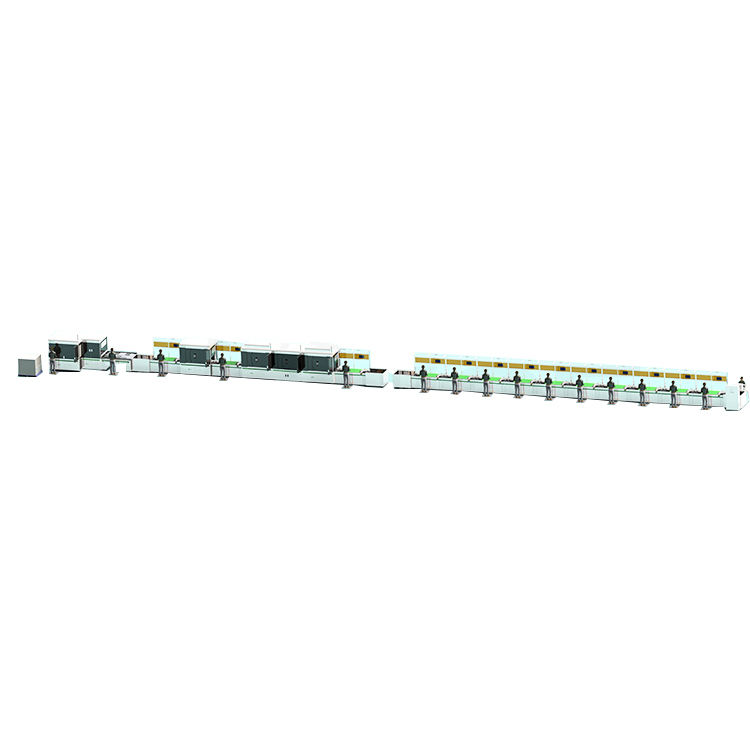

Battery Pack Automated Assembly Production LineThis production line is suitable for over 90% of cylindrical products in the market, with a high degree of standardization. Main processes include manual feeding, OCV sorting and scanning, secondary scanning, manual insertion into brackets, AI polarity detection, NG station, A-side laser welding, automatic fixture plate flipping, B-side laser welding, and manual fixture disassembly. It features a unique double-sided cross spot welding equipment, achieving one-time welding without flipping or moving. Industrial and Commercial/Home Energy Storage Module Laser Production LineThis automated assembly line consists of three main sections: cell sorting and processing, laser printer production line assembly, and manual assembly. It includes processes such as cell sorting, OCV testing, laser engraving, polarity detection, pole cleaning, bus line installation, laser welding, and DCIR detection.

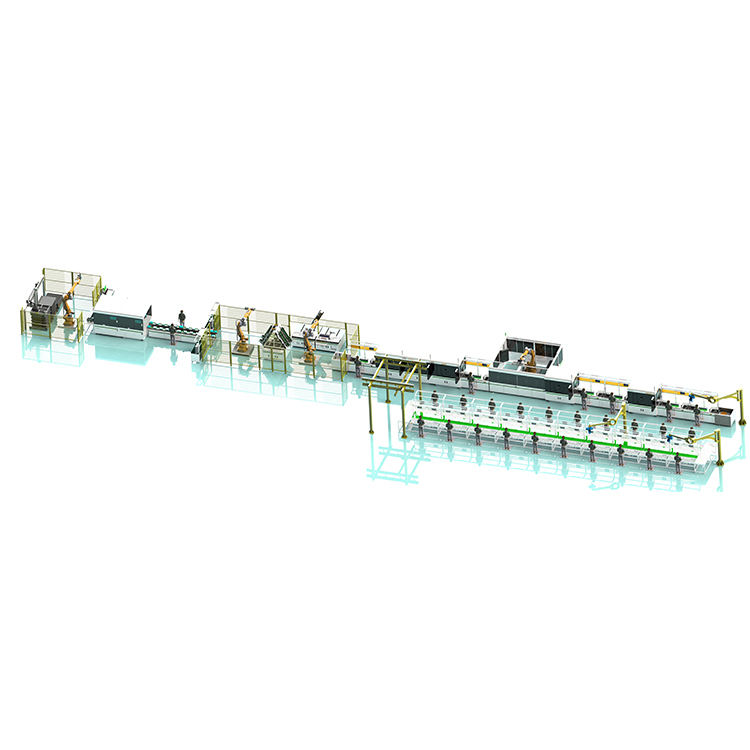

Industrial and Commercial/Home Energy Storage Module Laser Production LineThis automated assembly line consists of three main sections: cell sorting and processing, laser printer production line assembly, and manual assembly. It includes processes such as cell sorting, OCV testing, laser engraving, polarity detection, pole cleaning, bus line installation, laser welding, and DCIR detection. Industrial and Commercial Energy Storage Module Laser Production LineThis automated assembly line consists of three main sections: cell sorting, module line, and PACK assembly. It includes processes such as cell sorting, OCV testing, laser engraving, polarity detection, pole cleaning, laser welding, and DCIR detection. The production line uses six-axis robots for material handling and assembly, achieving a high degree of automation.

Industrial and Commercial Energy Storage Module Laser Production LineThis automated assembly line consists of three main sections: cell sorting, module line, and PACK assembly. It includes processes such as cell sorting, OCV testing, laser engraving, polarity detection, pole cleaning, laser welding, and DCIR detection. The production line uses six-axis robots for material handling and assembly, achieving a high degree of automation.

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support