News

Li-ion cell manufacturing: A look at processes and equipment

Introduction:

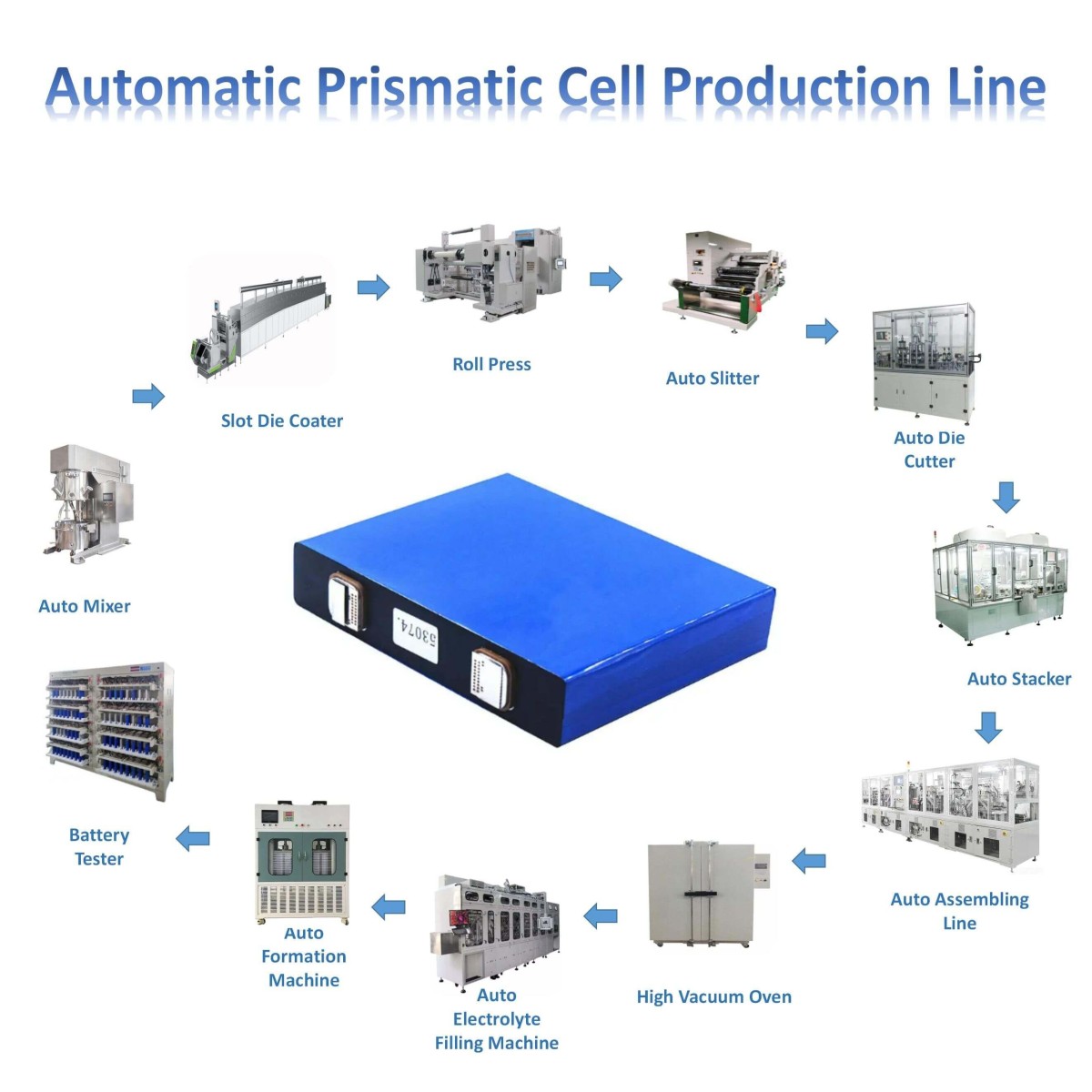

The lithium-ion battery assembly line plays a crucial role in the efficient production of energy storage batteries that have revolutionized various industries. This article highlights the significance of the assembly line in the manufacturing process of lithium-ion batteries, exploring its essential components and the impact it has on the production of high-performance energy storage solutions.

The Significance of the Lithium-Ion Battery Assembly Line:

1. Streamlined Production Process:

The assembly line enables a streamlined and efficient battery manufacturing process, where each step is carefully synchronized to optimize productivity and minimize production time.

2. Precise Battery Cell Assembly:

At the heart of the assembly line, precise battery cell assembly takes place. This step involves the careful alignment and stacking of anode, cathode, and separator materials, ensuring the formation of reliable battery cells.

3. Advanced Battery Coating Techniques:

The assembly line incorporates advanced #battery coating techniques to apply uniform and precise coatings to electrode materials, enhancing the battery's overall performance and energy storage capacity.

4. Automated Quality Control:

With automated quality control systems in place, the assembly line rigorously inspects each battery cell, identifying and addressing defects, ensuring that only high-quality batteries proceed to the next stage.

5. Efficient Electrolyte Filling:

The assembly line incorporates efficient electrolyte filling techniques, ensuring that the right amount of electrolyte is added to each battery cell, crucial for optimal electrochemical reactions.

6. Intelligent Battery Stacking:

Through the use of robotic automation, the assembly line achieves intelligent battery stacking, ensuring consistent and precise alignment of battery cells in larger modules and packs.

7. High-Precision Welding:

The assembly line employs high-precision #laser welding techniques to join electrode tabs, busbars, and terminals, creating secure electrical connections within the battery, critical for reliability.

8. Comprehensive Testing and Validation:

Before the batteries leave the assembly line, comprehensive testing and validation processes, including EOL testing and DCIR measurements, ensure that the batteries meet strict performance and safety standards.

The Impact on High-Performance Energy Storage Solutions:

1. Enhanced Energy Density:

The efficient assembly line processes contribute to improved energy density in lithium-ion batteries, enabling higher energy storage capacity within a compact form factor.

2. Longer Cycle Life:

Precise cell assembly and advanced coating techniques lead to longer battery cycle life, providing sustained performance over multiple charge and discharge cycles.

3. Faster Production Rates:

The streamlined assembly line significantly increases production rates, meeting the ever-growing demand for energy storage batteries in renewable energy and electric vehicle applications.

4. Reliable Battery Performance:

Automated quality control and thorough testing processes ensure that only reliable batteries reach the market, fostering customer trust and confidence in energy storage solutions.

In short:

The lithium-ion battery assembly line stands as a vital enabler of efficient energy storage battery production. Its precision, automation, and comprehensive testing processes contribute to the development of high-performance batteries that power the modern world. As the demand for energy storage solutions continues to soar, optimizing the assembly line's capabilities will play a pivotal role in advancing sustainable energy technologies and shaping a greener and more electrified future.

Awesome! Share to:

Related Posts

- The Energy Transition in 2025: Moving Forward or Falling Behind?

- The Importance of Lithium Battery Welding Machine in the Era of Electric Vehicle Rise

- The U.S. Battery market is about to boom

- The Future of Battery Production: Innovations and Market Trends

- The importance of rolling press machine in lithium battery production line

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support