News

The battery manufacturing industry is evolving rapidly, driven by the growing demand for efficient energy storage solutions. As the world transitions to renewable energy sources and electric vehicles, the need for advanced battery manufacturing technologies has never been greater. Among these technologies, the lithium battery manufacturing machine, battery formation equipment, and lead acid battery manufacturing machinery play crucial roles in ensuring the efficiency, reliability, and scalability of battery production. This article explores the latest trends in the battery manufacturing equipment market, highlighting the key innovations shaping the industry.

Lithium Battery Manufacturing Machine: Key to Future Energy Storage

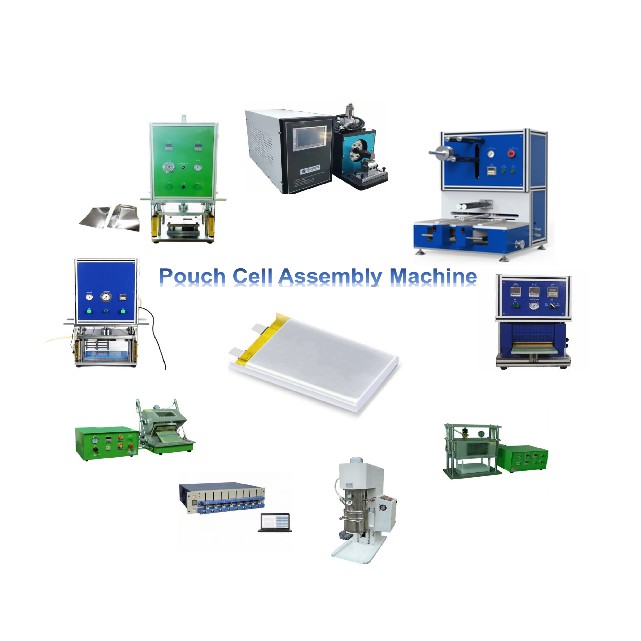

The lithium battery manufacturing machine is at the heart of modern battery production. As lithium-ion batteries become the preferred choice for electric vehicles (EVs), consumer electronics, and energy storage systems, manufacturers are relying on advanced machinery to meet the growing demand for high-performance cells. These machines automate critical steps in the battery production process, including electrode preparation, electrolyte filling, and cell assembly.

The lithium battery manufacturing machine is designed for precision and efficiency. It ensures that each cell is produced to the highest standards, maximizing energy density and longevity while minimizing defects. These machines also support the increasing need for mass production, enabling manufacturers to scale up operations while maintaining quality. With advancements in automation and AI, lithium battery manufacturing machines are becoming even more sophisticated, allowing for faster production times, reduced labor costs, and better quality control.

As the demand for lithium-ion batteries continues to rise, particularly in the electric vehicle and renewable energy sectors, the lithium battery manufacturing machine is expected to evolve further. Manufacturers are working on improving the overall efficiency of these machines, incorporating technologies like AI-driven optimization and enhanced automation to streamline the production process. Additionally, innovations in materials, such as solid-state electrolytes, are poised to further enhance the performance and safety of lithium batteries, making the lithium battery manufacturing machine an indispensable tool in the future of energy storage.

Battery Formation Equipment: Ensuring Optimal Performance

Battery formation is a critical step in the manufacturing process, ensuring that each battery performs optimally from the moment it is first used. Battery formation equipment is responsible for conditioning the battery by cycling it through charge and discharge processes. This helps to stabilize the electrolyte, optimize electrode performance, and ensure that the battery cells are capable of delivering reliable power over their expected lifespan.

The battery formation equipment is designed to handle large volumes of batteries while maintaining strict quality control. It allows manufacturers to test and validate each battery cell's capacity, voltage, and cycle life, ensuring that only high-quality cells make it to the final product. This process is particularly important for lithium-ion batteries, where performance, safety, and longevity are critical factors in determining the overall success of the product.

In the ever-evolving battery manufacturing equipment market, formation equipment is becoming more sophisticated. Manufacturers are developing advanced systems that not only enhance the speed and efficiency of the formation process but also integrate real-time monitoring and data analysis. These innovations enable manufacturers to detect any anomalies early in the production process, ensuring that defective cells are identified and removed before they reach the final product stage.

With the rise of electric vehicles and renewable energy storage, the role of battery formation equipment will continue to grow. As energy storage solutions become more critical to global sustainability efforts, manufacturers will rely on cutting-edge formation equipment to deliver high-performance batteries that meet the growing demands of these industries.

Lead Acid Battery Manufacturing Machinery: Meeting Traditional Needs in a Modern Market

While lithium-ion batteries are gaining significant market share, lead acid battery manufacturing machinery remains essential for producing one of the most widely used and affordable battery types in the world. Lead acid batteries continue to be a popular choice for automotive applications, uninterruptible power supplies (UPS), and other industrial uses due to their cost-effectiveness and reliable performance.

The lead acid battery manufacturing machinery is responsible for producing these batteries in large volumes while maintaining high standards of quality. These machines handle the assembly of lead plates, electrolyte filling, and battery formation. Despite the growing popularity of lithium-ion batteries, lead acid battery manufacturing machinery continues to evolve to meet modern standards, incorporating automation, improved safety features, and more efficient production techniques.

In addition to traditional uses, the demand for lead acid battery manufacturing machinery is also growing in niche markets such as renewable energy storage, where they provide a more affordable alternative to lithium-ion batteries. As manufacturers continue to innovate, lead acid battery manufacturing machinery is becoming more energy-efficient, with advancements in automation and material handling improving overall production efficiency.

The future of lead acid battery manufacturing machinery lies in continued improvements in efficiency, safety, and scalability. While lithium-ion batteries may dominate the electric vehicle market, lead acid batteries will remain a crucial component in many other industries, making the machinery for their production an essential part of the global battery manufacturing ecosystem.

Battery Manufacturing Equipment Market: Trends and Growth

The battery manufacturing equipment market is experiencing rapid growth, driven by the increasing demand for energy storage solutions. As electric vehicles, renewable energy, and portable devices continue to rise in popularity, the need for efficient and scalable battery production is more important than ever. Manufacturers are investing heavily in advanced machinery and automation to meet these demands and stay competitive in the market.

Key trends in the battery manufacturing equipment market include the development of smarter, more efficient machinery. Automation is becoming a central focus, as it allows manufacturers to streamline production, reduce human error, and lower labor costs. Additionally, advancements in AI and machine learning are enabling manufacturers to optimize production processes and improve quality control, ensuring that only the highest-quality batteries reach the market.

The market for battery manufacturing equipment is also being shaped by the shift towards sustainable energy solutions. As the world moves toward greener technologies, battery production must become more sustainable as well. Manufacturers are increasingly looking for ways to reduce energy consumption, minimize waste, and incorporate recyclable materials into the production process. The battery manufacturing equipment market will continue to grow as these trends evolve, with manufacturers striving to create more efficient, cost-effective, and environmentally friendly production methods.

The Future of Battery Manufacturing: Innovation and Sustainability

As the global shift toward renewable energy accelerates, the demand for batteries that can store and deliver energy efficiently will continue to grow. Innovations in lithium battery manufacturing machines, battery formation equipment, and lead acid battery manufacturing machinery will play a central role in shaping the future of energy storage. Manufacturers are focusing on improving the performance, safety, and sustainability of batteries, which will be crucial for meeting the needs of the electric vehicle and renewable energy industries.

One of the key areas of focus for future battery manufacturing will be sustainability. As more industries adopt electric vehicles and renewable energy solutions, manufacturers are working to create more sustainable production processes. This includes improving the efficiency of machinery, using environmentally friendly materials, and reducing the environmental impact of production.

Innovation in the battery manufacturing equipment market will also drive the development of new battery chemistries and technologies, such as solid-state batteries and advanced lithium-ion technologies. These advancements promise to deliver higher energy densities, longer lifespans, and improved safety features, making them ideal for a wide range of applications, from electric vehicles to grid-scale energy storage.

In conclusion, the future of battery manufacturing lies in innovation, efficiency, and sustainability. As demand for energy storage solutions continues to rise, the lithium battery manufacturing machine, battery formation equipment, and lead acid battery manufacturing machinery will remain critical components of the manufacturing process. By investing in advanced technologies and improving production efficiency, manufacturers can meet the growing global demand for high-performance, sustainable batteries.

Awesome! Share to:

Related Posts

- The Energy Transition in 2025: Moving Forward or Falling Behind?

- The Importance of Lithium Battery Welding Machine in the Era of Electric Vehicle Rise

- The U.S. Battery market is about to boom

- The Future of Battery Production: Innovations and Market Trends

- The importance of rolling press machine in lithium battery production line

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support