News

Unlocking the Future of Energy: Lithium-Ion Battery Assembly Machines

In a world that increasingly relies on clean energy and efficient battery technology, lithium-ion batteries stand out as a pivotal solution. With the rising demand for electric vehicles and renewable energy storage, the production of lithium batteries is experiencing unprecedented growth. To streamline manufacturing processes and enhance productivity, investing in cutting-edge lithium-ion battery assembly machines has never been more critical.

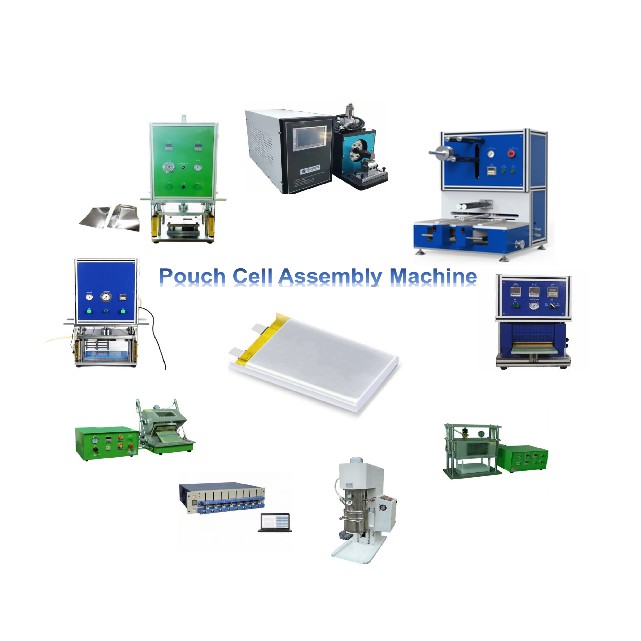

The Heart of the Battery Production Line

At the core of an efficient battery production line, lithium-ion battery assembly machines play a vital role. They automate complex tasks, thereby ensuring that every battery produced meets the highest standards of quality and performance. From cell production to module assembly, these machines significantly reduce human error, improve production speed, and lower operational costs. With advanced technology integrated into their design, these machines ensure optimal efficiency at every stage of battery assembly, making them indispensable in today's fast-paced manufacturing environments.

Precision Engineering with Lithium Battery Welding Machines

Welding is a crucial step in lithium battery assembly, and the choice of welding machines can make or break production quality. Lithium battery welding machines ensure precision and consistency during the assembly of battery cells and packs. Equipped with state-of-the-art laser welding technology, these machines create incredibly strong and durable joints, which are essential for maximizing battery performance and longevity. Reliable welding solutions facilitate enhanced energy density and safety, making them a must-have for serious battery manufacturers.

Choosing the Right Battery Assembly Line Manufacturers

When it comes to investing in lithium-ion battery assembly machines, selecting the right battery assembly line manufacturers is paramount. A reputable manufacturer will not only provide high-quality machinery but also offer excellent customer support, maintenance services, and technological upgrades. Look for manufacturers with a proven track record in the battery industry, as their expertise can guide you through the nuances of lithium battery production. A quality partnership can lead to increased productivity, reduced downtime, and a better overall return on investment, ensuring that your production line consistently meets the escalating market demands.

The industry is continuously evolving, and innovations in lithium-ion battery assembly machines are paving the way for the future of energy storage. With advancements in automation and artificial intelligence, modern assembly lines are becoming smarter and more adaptable. This allows manufacturers to easily scale production based on market needs while maintaining stringent quality controls. Whether you're looking to upgrade an existing line or build a new production facility from the ground up, investing in innovative technology ensures you're at the forefront of the lithium battery revolution.

Conclusion: Propel Your Business Forward

The demand for lithium-ion batteries is set to grow exponentially, making now the perfect time to invest in high-quality assembly machines. By incorporating advanced lithium battery welding machines and collaborating with trusted battery assembly line manufacturers, you can elevate your production capabilities and secure your business’s future in the vibrant energy market. Don't just keep up with the competition—lead the charge toward a sustainable future with cutting-edge lithium-ion battery assembly technologies. Your next step to success starts here!

Awesome! Share to:

Related Posts

- The Energy Transition in 2025: Moving Forward or Falling Behind?

- The Importance of Lithium Battery Welding Machine in the Era of Electric Vehicle Rise

- The U.S. Battery market is about to boom

- The Future of Battery Production: Innovations and Market Trends

- The importance of rolling press machine in lithium battery production line

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support