1. One-Stop Service

2. Modular Flexible Design

3. Selectable Automation Levels

4. Intelligent Manufacturing Support

5. Quality Monitoring Assurance

6. High Efficiency and High Productivity

7. Human-Centric Engineering Optimization

8. Safe and Environmentally Friendly Design

9. Technical Training and Maintenance

10. Customized Development

Product Description

1: Keywords:

Automated assembly line, multi-type battery production, laser welding, energy storage.

2: Introduction:

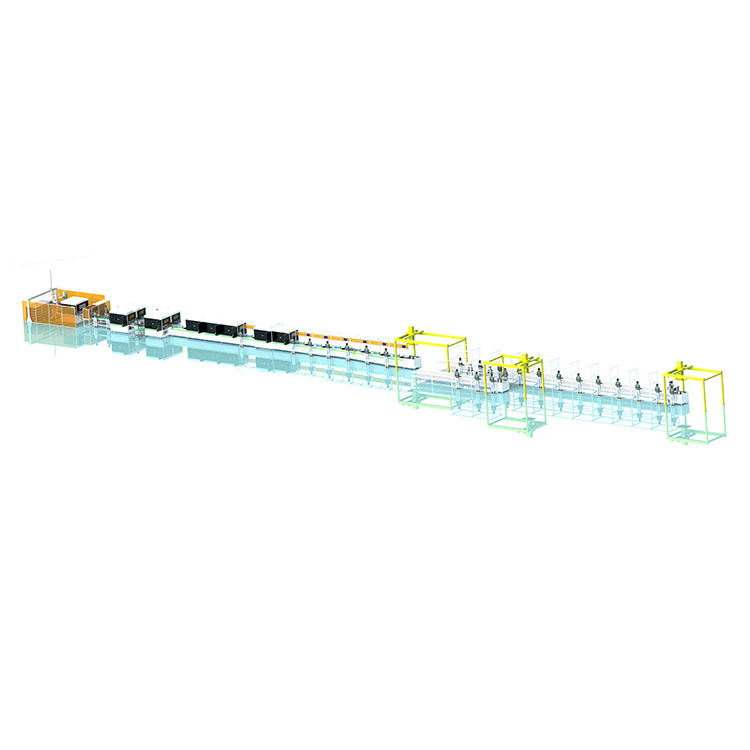

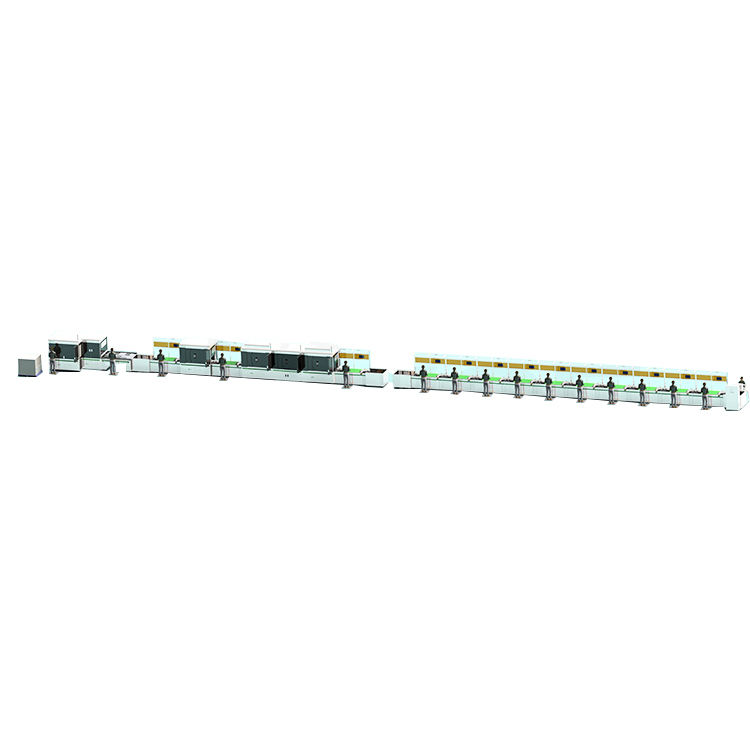

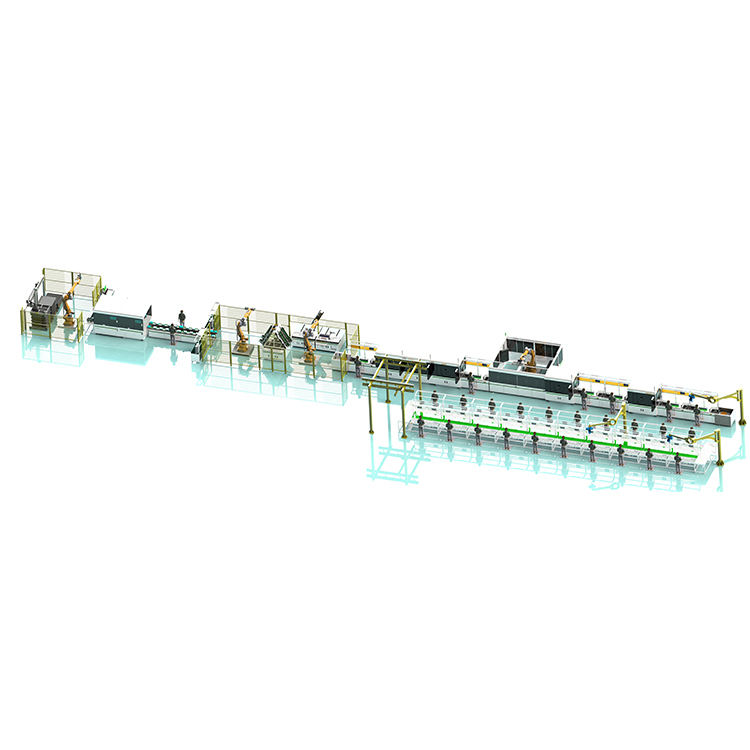

This production line is mainly used for the post-application process of large and small cylindrical and prismatic batteries. Key processes include cell feeding, scanning of large and small cylindrical cells, secondary scanning, manual bracket installation, prismatic cell feeding, prismatic and pouch cell scanning and sorting (4+1), glue dispensing, laser cleaning, manual tightening, pole laser cleaning, Al detection, nickel plate installation and reflow, laser welding, single-side resistance welding, etc.

3: Technical Specifications:

Dimensions: 4000cm×210cm×200cm

Voltage: 220V

Compatible Battery Types: Large/small cylindrical batteries, prismatic batteries

4: Technical Features:

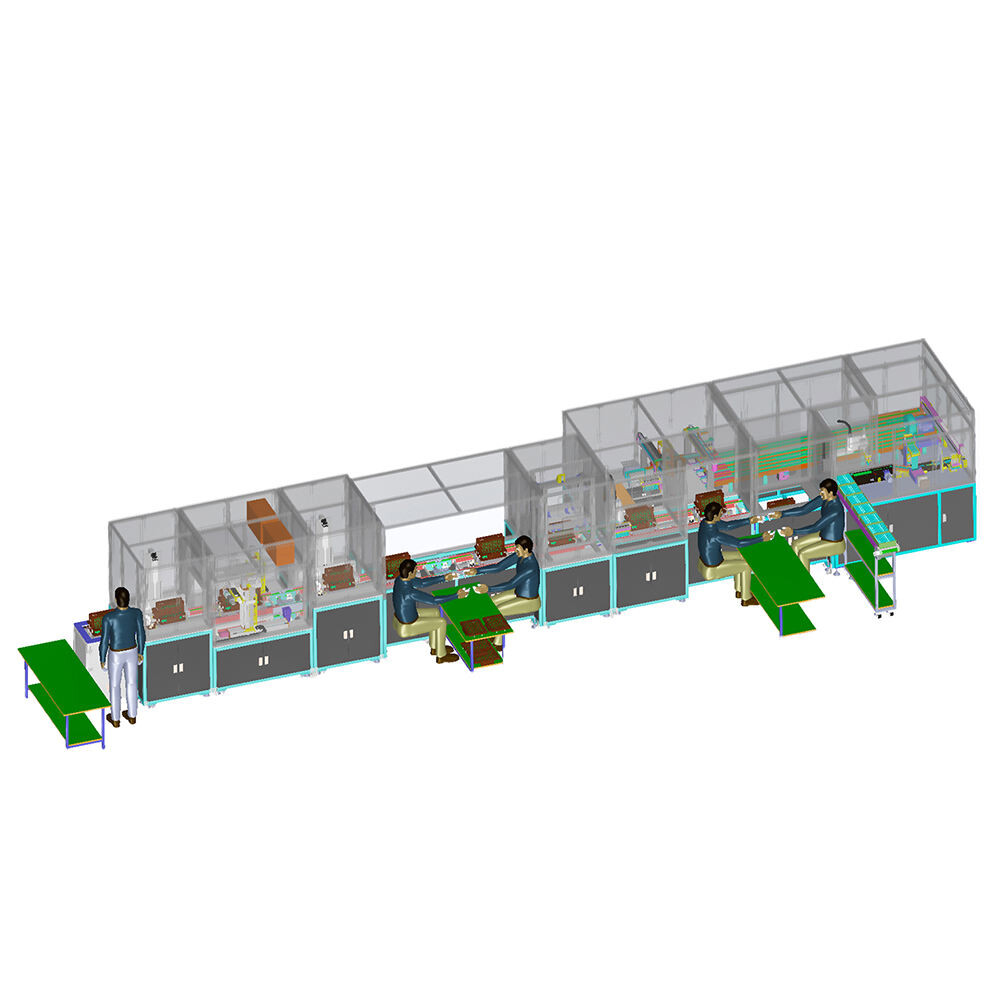

Integrated MES system for data acquisition, processing, tracing, and online quality control.

High degree of automation and high production efficiency.

Integrates multiple production lines into one process compatible with cylindrical/prismatic aluminum shell batteries.

Customizable according to specific customer needs.

5: Key Advantages:

Reduce labor costs.

Improve product quality.

Increase productivity.

6: Application:

New energy vehicle battery production, energy storage system battery production, multi-type battery production.

Lithium Battery Intelligent Production Line Solution

Partners

Certificates

Send me a free quote

Related Products

Industrial and Commercial Energy Storage Module Laser Production LineThis automated assembly line consists of three main sections: cell sorting, module line, and PACK assembly. It includes processes such as cell sorting, OCV testing, laser engraving, polarity detection, pole cleaning, bus line installation, laser welding, and pressure resistance testing.

Industrial and Commercial Energy Storage Module Laser Production LineThis automated assembly line consists of three main sections: cell sorting, module line, and PACK assembly. It includes processes such as cell sorting, OCV testing, laser engraving, polarity detection, pole cleaning, bus line installation, laser welding, and pressure resistance testing. Battery Pack Automated Assembly Production LineThis production line is suitable for over 90% of cylindrical products in the market, with a high degree of standardization. Main processes include manual feeding, OCV sorting and scanning, secondary scanning, manual insertion into brackets, AI polarity detection, NG station, A-side laser welding, automatic fixture plate flipping, B-side laser welding, and manual fixture disassembly. It features a unique double-sided cross spot welding equipment, achieving one-time welding without flipping or moving.

Battery Pack Automated Assembly Production LineThis production line is suitable for over 90% of cylindrical products in the market, with a high degree of standardization. Main processes include manual feeding, OCV sorting and scanning, secondary scanning, manual insertion into brackets, AI polarity detection, NG station, A-side laser welding, automatic fixture plate flipping, B-side laser welding, and manual fixture disassembly. It features a unique double-sided cross spot welding equipment, achieving one-time welding without flipping or moving. Advanced New Energy Lithium Battery PACK Automated Assembly Production Line SystemLithium battery assembly, Automated production line, Battery pack manufacturing, New energy battery, Industry 4.0, Smart manufacturing, High-precision automation

Advanced New Energy Lithium Battery PACK Automated Assembly Production Line SystemLithium battery assembly, Automated production line, Battery pack manufacturing, New energy battery, Industry 4.0, Smart manufacturing, High-precision automation Industrial and Commercial/Home Energy Storage Module Laser Production LineThis automated assembly line consists of three main sections: cell sorting and processing, laser printer production line assembly, and manual assembly. It includes processes such as cell sorting, OCV testing, laser engraving, polarity detection, pole cleaning, bus line installation, laser welding, and DCIR detection.

Industrial and Commercial/Home Energy Storage Module Laser Production LineThis automated assembly line consists of three main sections: cell sorting and processing, laser printer production line assembly, and manual assembly. It includes processes such as cell sorting, OCV testing, laser engraving, polarity detection, pole cleaning, bus line installation, laser welding, and DCIR detection.

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support