1. One-Stop Service

2. Modular Flexible Design

3. Selectable Automation Levels

4. Intelligent Manufacturing Support

5. Quality Monitoring Assurance

6. High Efficiency and High Productivity

7. Human-Centric Engineering Optimization

8. Safe and Environmentally Friendly Design

9. Technical Training and Maintenance

10. Customized Development

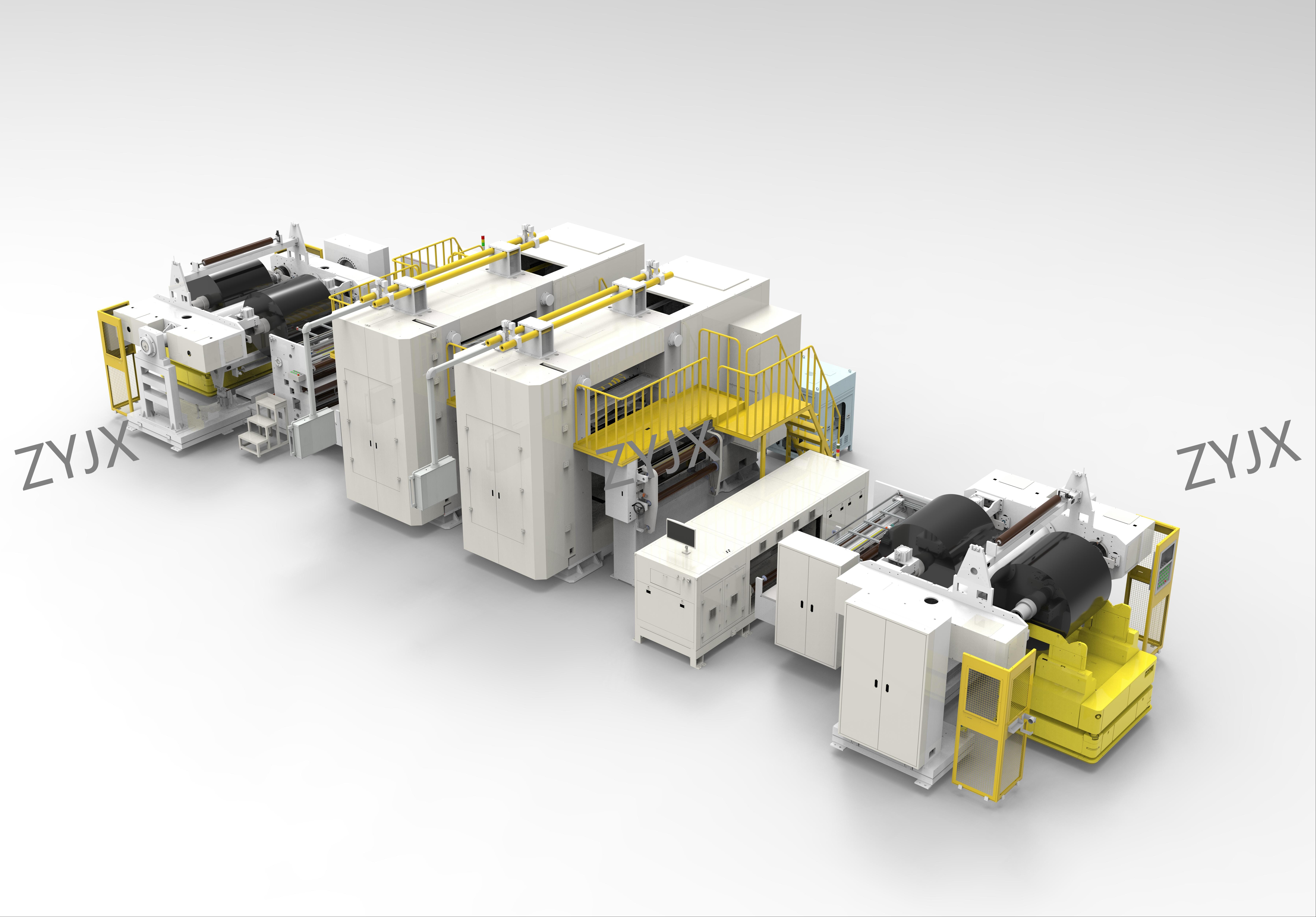

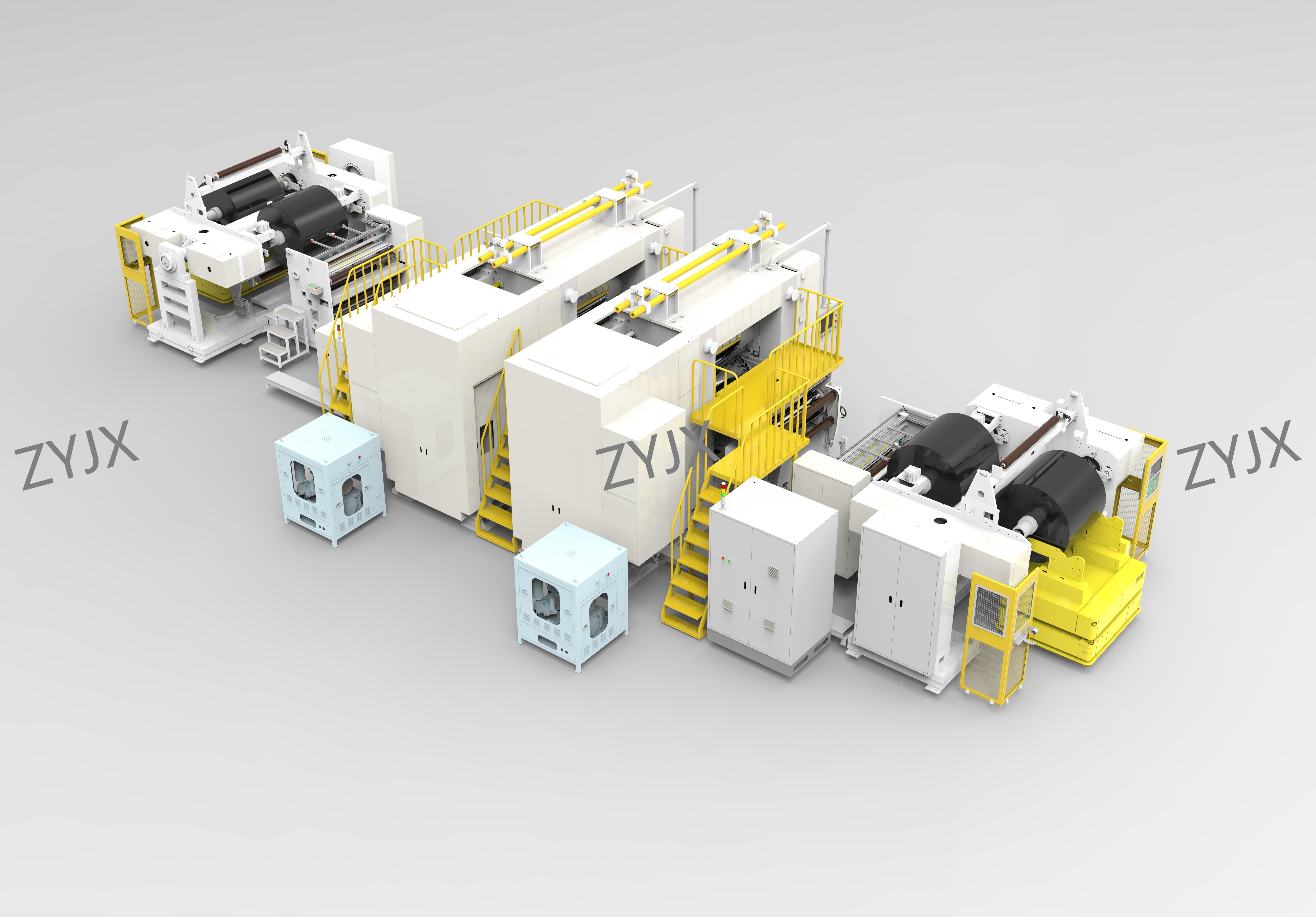

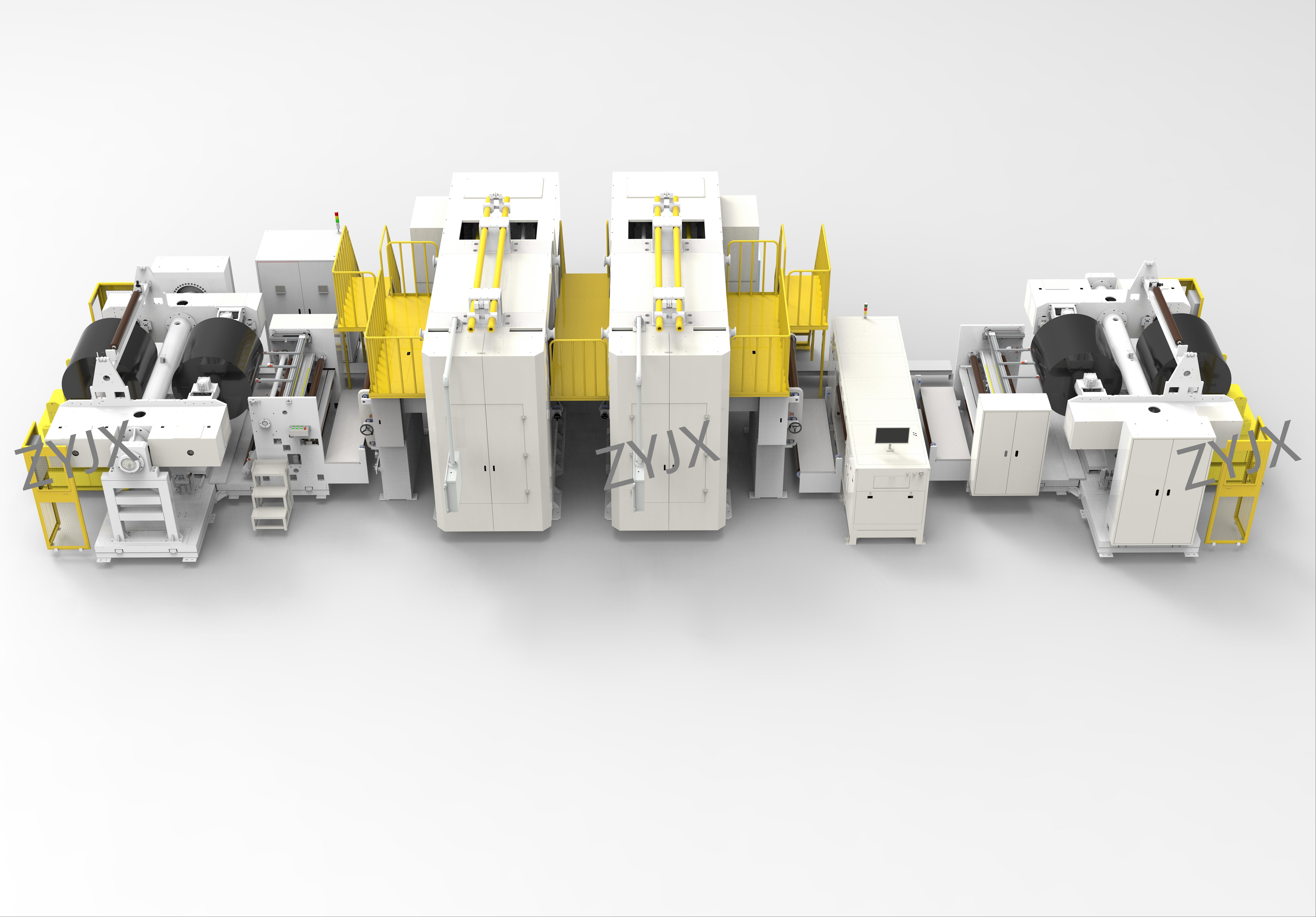

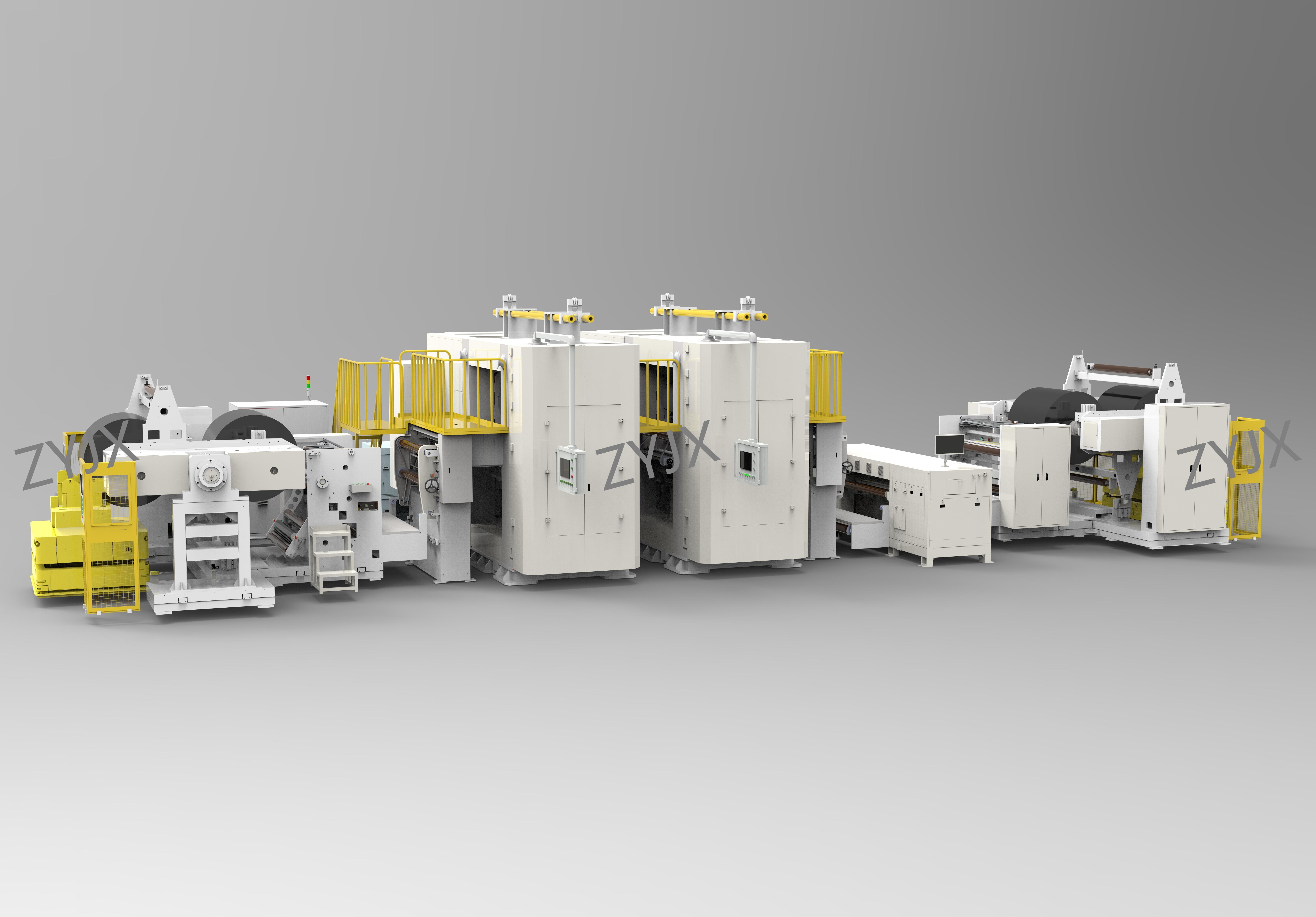

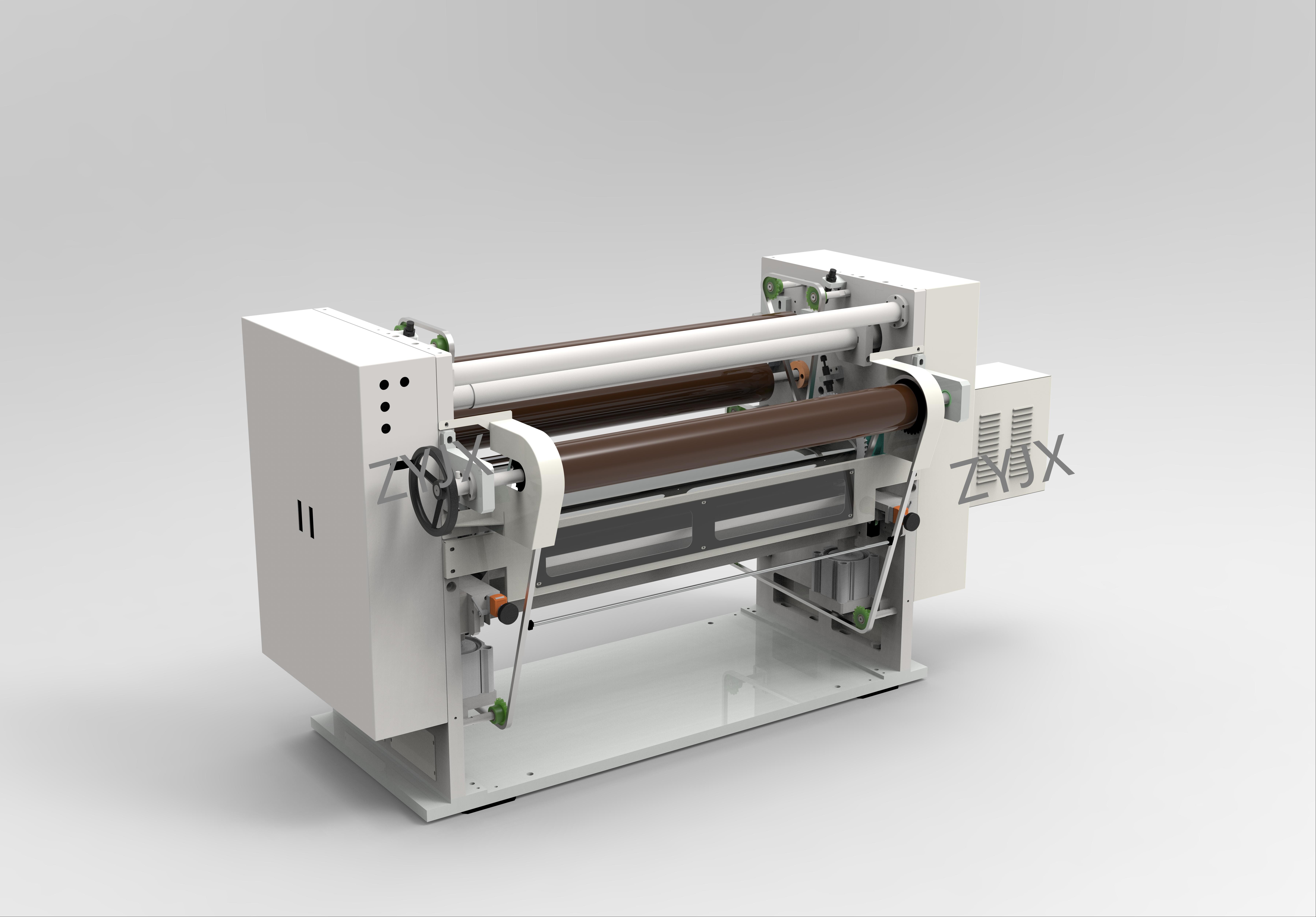

Product Description

1: Keywords:

Negative electrode, double-machine continuous rolling, automatic splicing, integrated machine

2: Introduction:

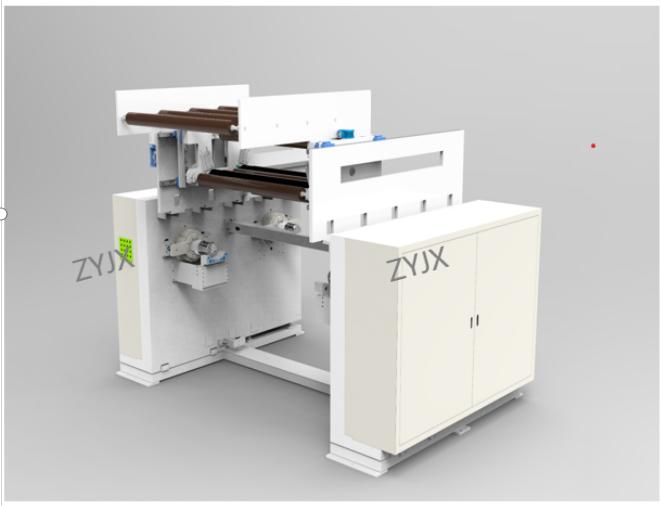

This is an integrated equipment for battery negative electrode production, combining double-machine continuous rolling and automatic splicing functions, suitable for wide-width negative electrode material production and processing.

3: Process Flow

Top process:Transfer - Automatic Connection - Technology Docking - Deduplication - Pull - Main - Publish

Bottom process:Transfer Collection - Automatic Connection - Technology Docking - Test - Pull - Main - Clear

4: Technical specifications:

Suitable material width: 1400mm

Production speed: 80~150m/min

Unwinding roll diameter: 1000mm~1300mm

Rewinding roll diameter: 1000mm

Splicing success rate: 95~99%

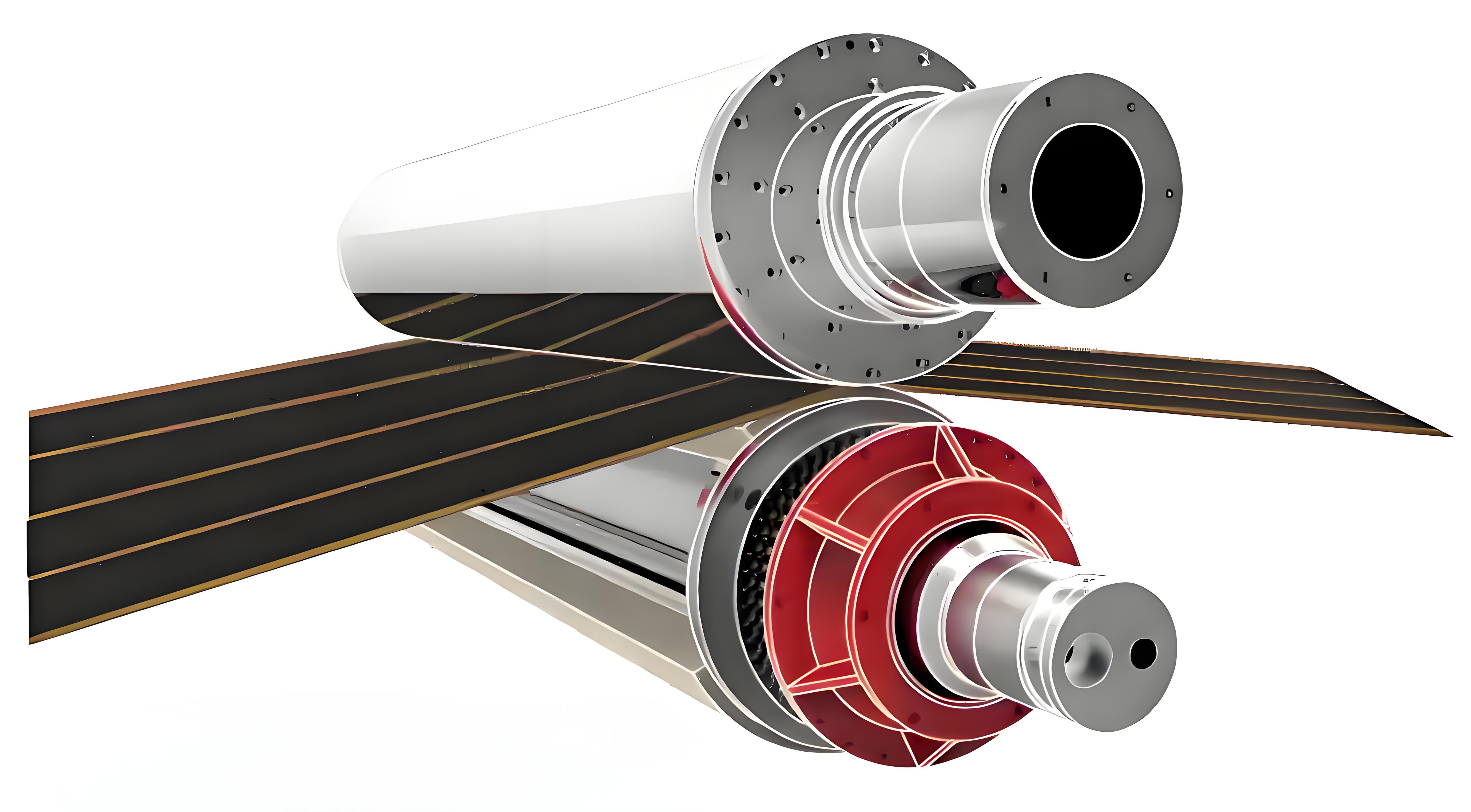

Roll pressing precision: ±0.002mm

Unwinding tension control precision: ±5N

Stretching tension control precision: ±5N

Rolling roll precision: ±0.001mm (cylindricity, straightness, etc.)

5:Technical Features:

Double-machine continuous rolling design

Automatic splicing function

High-precision roll pressing

Optional pressure closed-loop and roll gap closed-loop control

Unwinding with speed closed-loop and tension closed-loop control

High-precision stretching tension control

Special surface treatment for rolling rolls (chrome-plated or tungsten carbide)

6:Application:

Battery negative electrode material production.

Lithium Battery Intelligent Production Line Solution

Partners

Certificates

Send me a free quote

Related Products

Shower Brush Roll DeviceThis device is used to actively remove dust particles adhered to the roll surface, keeping the roll surface clean.

Shower Brush Roll DeviceThis device is used to actively remove dust particles adhered to the roll surface, keeping the roll surface clean. Stretching and Flattening DeviceUsed to eliminate the wave edges produced during the rolling process of continuously or continuously slit-coated battery electrodes.

Stretching and Flattening DeviceUsed to eliminate the wave edges produced during the rolling process of continuously or continuously slit-coated battery electrodes. Special Roll Surface Treatment

Special Roll Surface Treatment Positioning Automatic Reel Changing MechanismNo need for a turret mechanism to switch between reel A and reel B. It eliminates the complex control, complicated mechanism, and large space occupation of the turret automatic reel-to-reel mechanism. Instead, it adopts a movable material arm to complete the reel switching. This structure has low cost, simple operation, and is suitable for large reel diameter and high-speed equipment.

Positioning Automatic Reel Changing MechanismNo need for a turret mechanism to switch between reel A and reel B. It eliminates the complex control, complicated mechanism, and large space occupation of the turret automatic reel-to-reel mechanism. Instead, it adopts a movable material arm to complete the reel switching. This structure has low cost, simple operation, and is suitable for large reel diameter and high-speed equipment.

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support