1. One-Stop Service

2. Modular Flexible Design

3. Selectable Automation Levels

4. Intelligent Manufacturing Support

5. Quality Monitoring Assurance

6. High Efficiency and High Productivity

7. Human-Centric Engineering Optimization

8. Safe and Environmentally Friendly Design

9. Technical Training and Maintenance

10. Customized Development

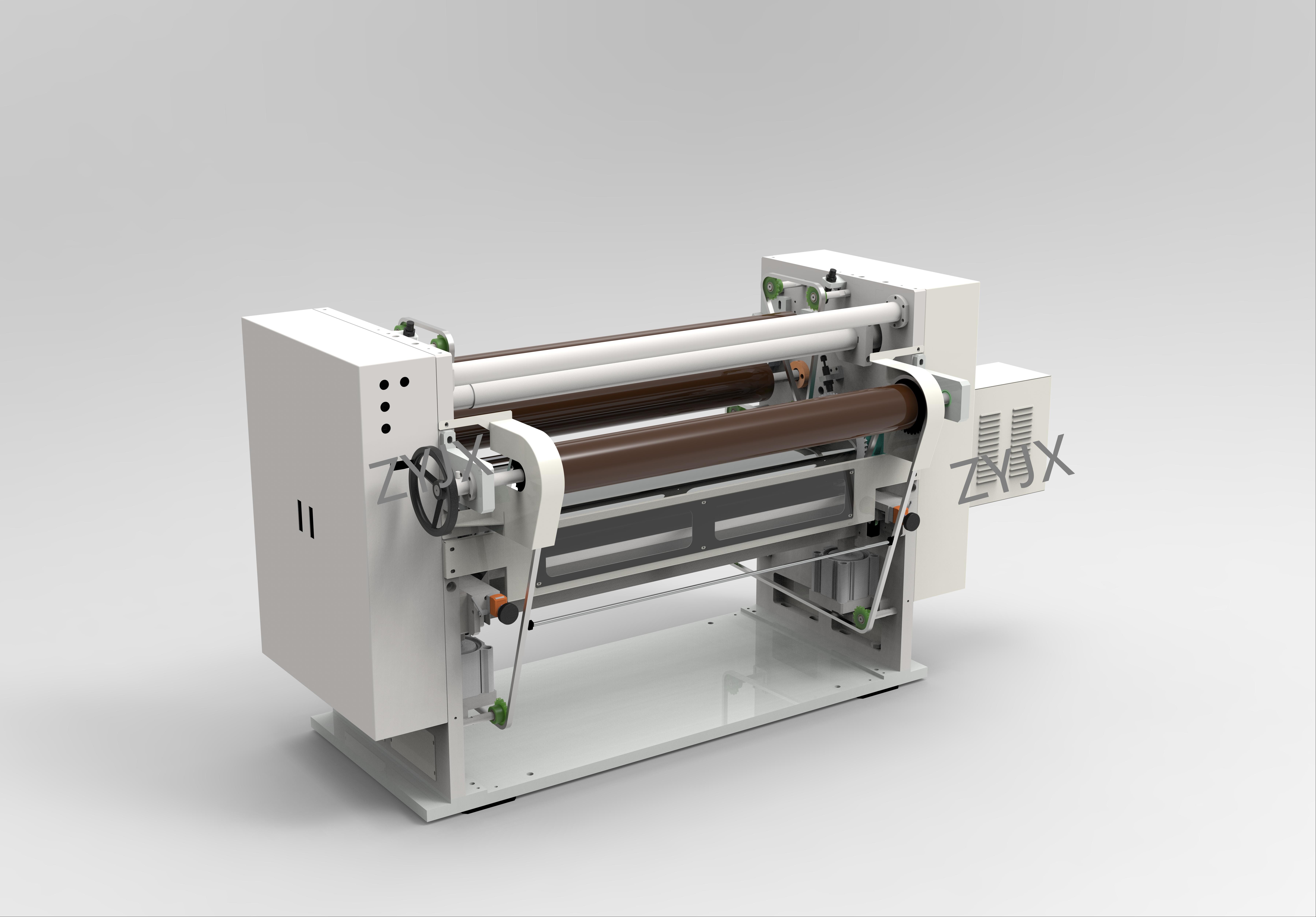

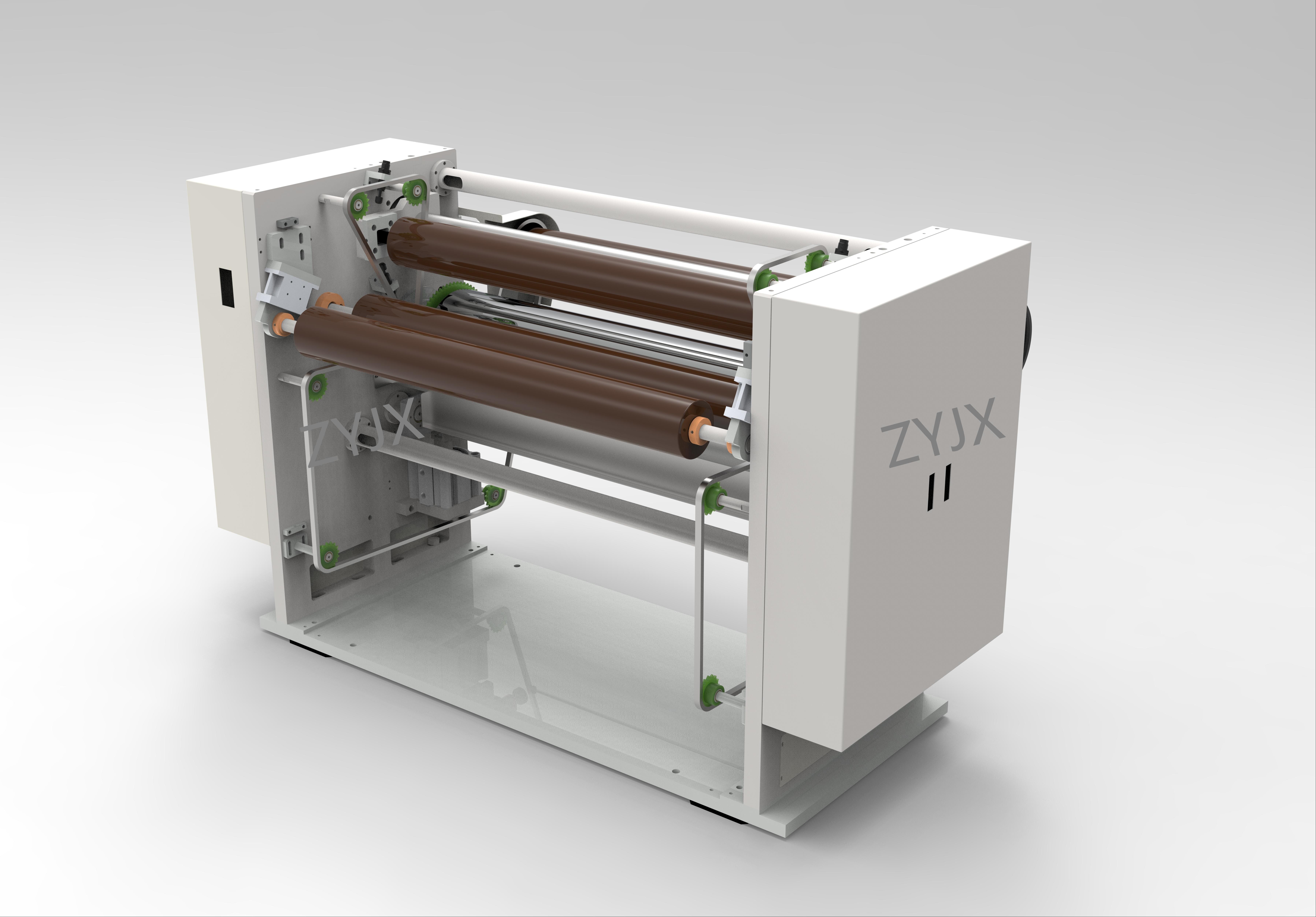

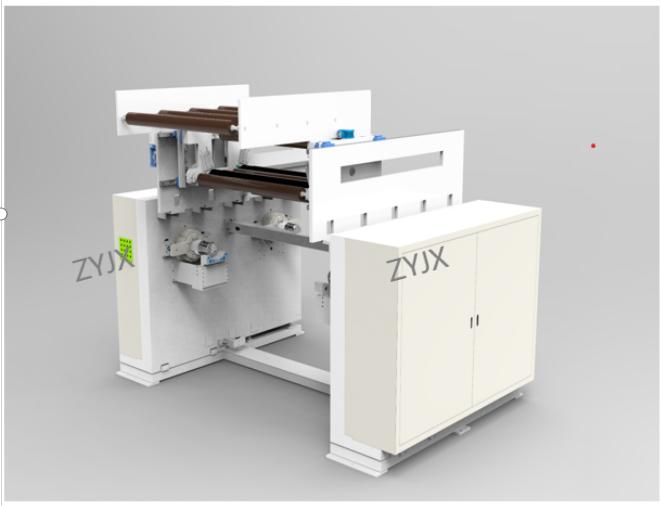

Product Description

1: Keywords:

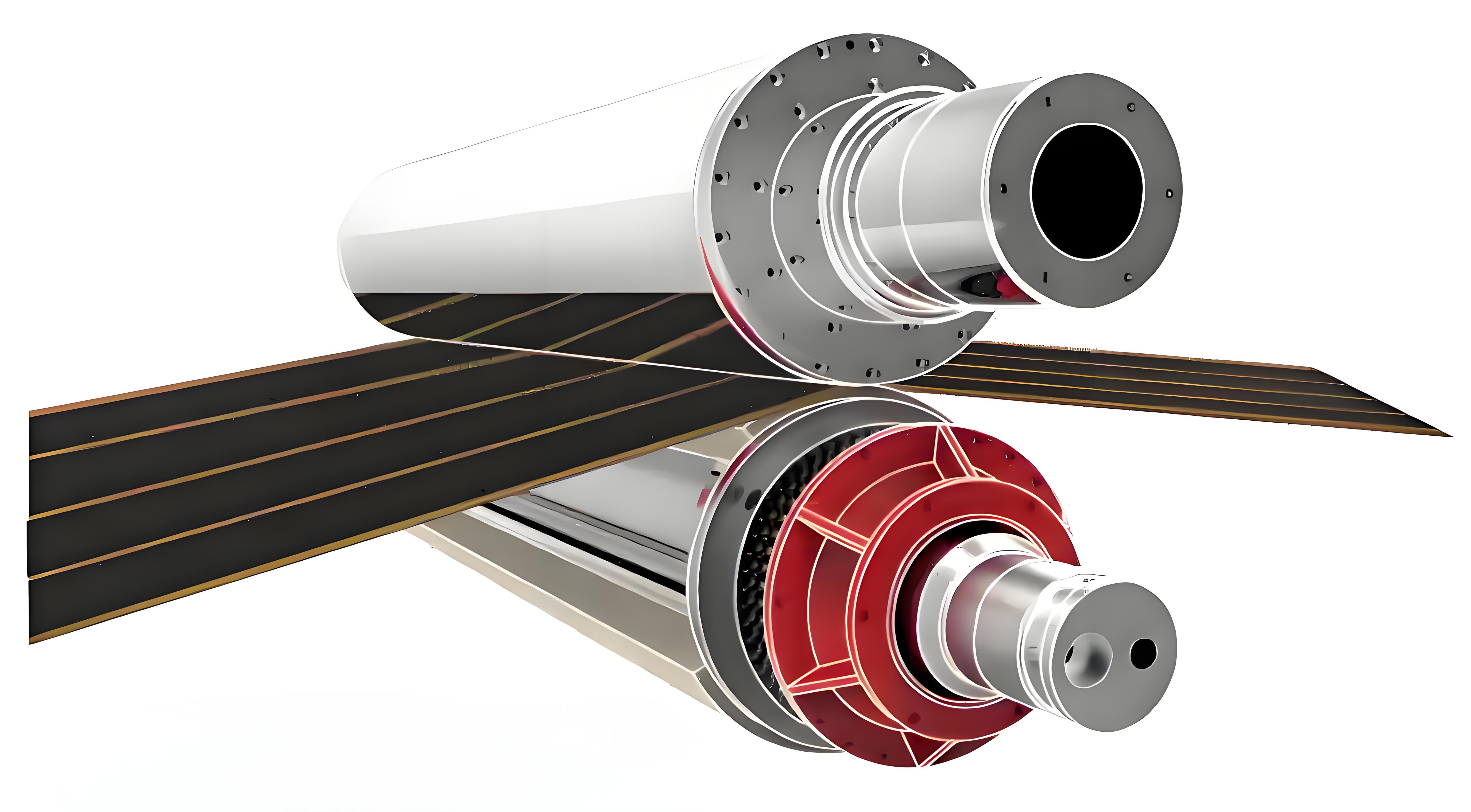

Battery electrode, wave edge, stretching, flattening, tension control, corrugated roll, plastic deformation

2: Introduction:

Used to eliminate the wave edges produced during the rolling process of continuously or continuously slit-coated battery electrodes.

3: Technical Specifications:

Traction roll diameter: φ200mm.

Pinch roll diameter: φ120mm.

Tension adjustment range: 10~1000N.

Tension control accuracy: ≤±2N.

4: Technical Features:

Includes tension isolation traction, swinging roll stretching, tension detection, and auxiliary threading devices.

A corrugated roll is made according to the product width, and appropriate tension is applied to the material strip.

Plastic deformation occurs in the non-coated foil area, reducing uneven deformation along the entire length of the electrode.

This eliminates or reduces the formation of wrinkles in the transition area.

Traction roll specification: φ200mm, with a hard chrome plated surface.

Pinch roll specification: φ120mm, with a tri-polymer rubber surface.

PLC + low-friction cylinder + servo motor dual closed-loop tension control, with a digital display showing the tension value.

Tension adjustment range: 10~1000N, control accuracy ≤±2N.

5: Application:

Battery electrode production line.

Lithium Battery Intelligent Production Line Solution

Partners

Certificates

Send me a free quote

Related Products

Shower Brush Roll DeviceThis device is used to actively remove dust particles adhered to the roll surface, keeping the roll surface clean.

Shower Brush Roll DeviceThis device is used to actively remove dust particles adhered to the roll surface, keeping the roll surface clean. Special Roll Surface Treatment

Special Roll Surface Treatment Positioning Automatic Reel Changing MechanismNo need for a turret mechanism to switch between reel A and reel B. It eliminates the complex control, complicated mechanism, and large space occupation of the turret automatic reel-to-reel mechanism. Instead, it adopts a movable material arm to complete the reel switching. This structure has low cost, simple operation, and is suitable for large reel diameter and high-speed equipment.

Positioning Automatic Reel Changing MechanismNo need for a turret mechanism to switch between reel A and reel B. It eliminates the complex control, complicated mechanism, and large space occupation of the turret automatic reel-to-reel mechanism. Instead, it adopts a movable material arm to complete the reel switching. This structure has low cost, simple operation, and is suitable for large reel diameter and high-speed equipment. 800*700 Slitting MachineThis is a precision slitting equipment used for battery material production, suitable for accurate slitting of medium to small width battery materials.

800*700 Slitting MachineThis is a precision slitting equipment used for battery material production, suitable for accurate slitting of medium to small width battery materials.

Provide you with an integrated solution

24/7 before-sales and after-sales services

Comprehensive technical support